Required web technologies and cookies make our website technically accessible to and usable for you. This applies to fundamental base functionalities such as navigation on the website, correct display in your internet browser or requesting your consent. Without these web technologies and cookies our website does not work.

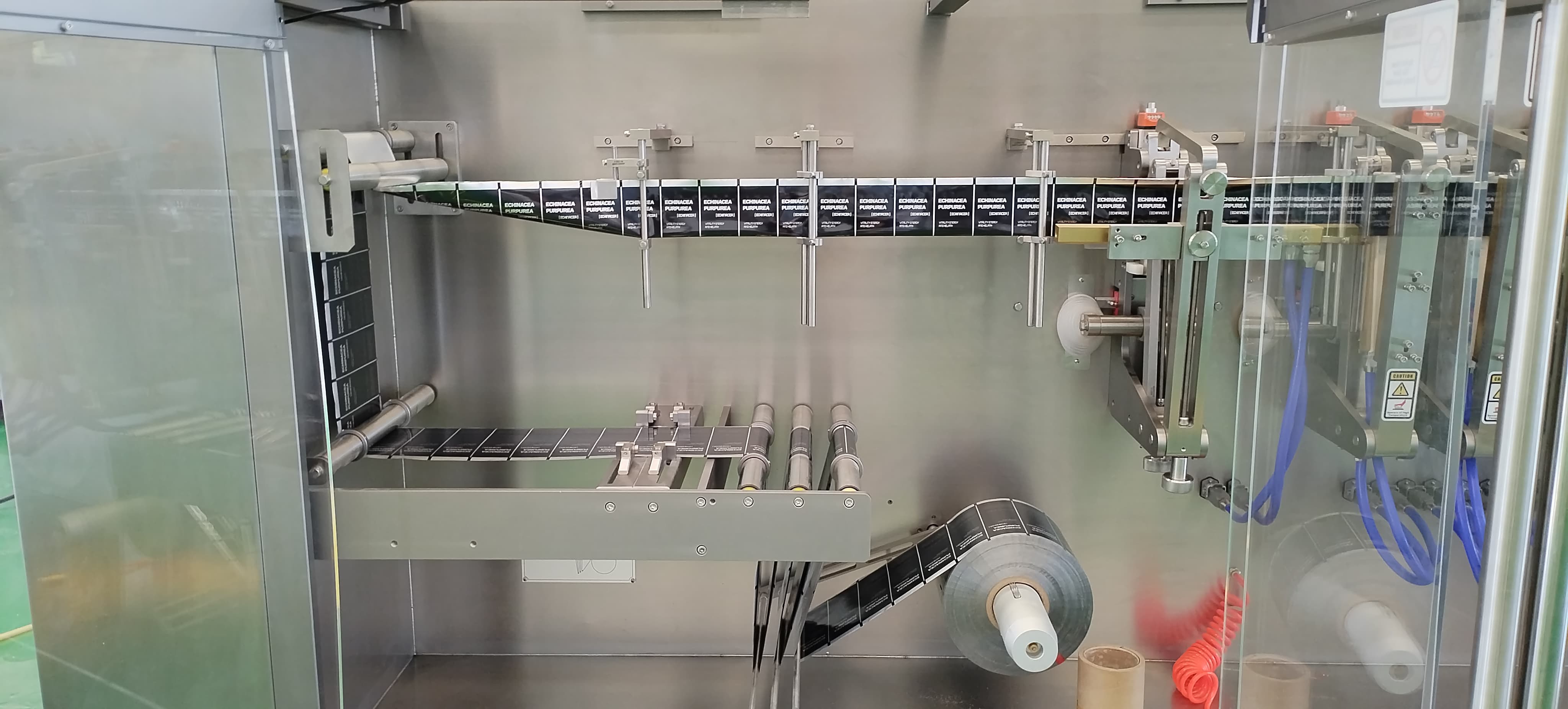

Horizontal 4-Side Seal Sachet Packaging Machines: Boost Efficiency & Product Appeal

In the competitive world of product packaging, efficiency and presentation are paramount. Horizontal 4-side seal sachet packaging machines have emerged as a game-changer for industries seeking to enhance their packaging lines. These machines automate the process of creating hermetically sealed, aestheticallay pleasing sachets, ideal for a wide range of products. But what exactly makes them so effective, and why are they becoming the preferred choice for many businesses? This article delves into the workings, advantages, and applications of these advanced packaging systems, providing a clear understanding of their transformative potential.

What Are Horizontal 4-Side Seal Sachet Packaging Machines and How Do They Work?

A horizontal 4-side seal sachet packaging machine is an automated system designed to form, fill, and seal packaging materials into sachets sealed on all four edges. Unlike traditional packaging that might have a back seal or be open on one end, the four-side seal offers a complete enclosure, often resulting in a more premium and secure package. The process begins with a flat roll of packaging film, which is fed horizontally into the machine. The film is then precisely formed into pouches, filled with the product—be it granules, powders, liquids, or solid items—and subsequently sealed on all four sides before being cut into individual sachets8. This method is particularly noted for producing a clean, symmetrical package with a high-quality finish.

The operation is typically governed by advanced Programmable Logic Controller (PLC) systems and servo motors, which ensure high precision in bag length, sealing time, and filling accuracy110. Many models feature intuitive touchscreen interfaces, allowing operators to easily set parameters like bag dimensions and production speed1. This level of automation not only streamlines the packaging process but also minimizes human error, leading to consistent and reliable output.

Why Should Your Business Consider a Horizontal 4-Side Seal Machine? Key Advantages Unveiled

Investing in a horizontal 4-side seal packaging machine brings a host of benefits that can significantly impact your productivity and bottom line.

Superior Seal Integrity and Product Protection: The four-side seal creates a robust barrier against external contaminants, moisture, and air1. This is crucial for preserving the freshness, potency, and shelf life of sensitive products like pharmaceuticals, food items, and chemicals. The sealed edges are strong and less prone to leakage compared to other seal types.

Enhanced Aesthetic Appeal and Branding Space: These machines produce sachets with a flat, symmetrical appearance, providing a larger, more uniform surface area for branding and product information6. This is invaluable for marketing, as it allows for high-quality printing and an overall more professional look that can attract consumers on retail shelves.

High Efficiency and Flexibility: Designed for continuous motion operation, these machines can achieve impressive speeds, often ranging from 20 to over 100 bags per minute, depending on the model and product39. They offer remarkable flexibility, easily accommodating changes in bag sizes and materials through simple adjustments on the control panel. This makes them ideal for production runs of varying sizes and specifications5.

Reduced Material Waste and Operational Costs: Advanced features like photoelectric tracking and automatic edge correction ensure precise alignment of the packaging film, minimizing material waste15. The efficiency of the sealing process itself also contributes to lower energy consumption and reduced downtime, leading to significant cost savings over time.

Which Industries Benefit Most from This Packaging Technology?

The versatility of horizontal 4-side seal machines makes them suitable for a diverse array of sectors.

Food and Beverage: Perfect for packaging coffee powder, spices, sugar, sauces, and other granular or liquid food products410. The excellent seal integrity helps maintain flavor and freshness.

Pharmaceutical and Medical: Widely used for packaging sutures, sterile wipes, ointments, and single-dose medications into sterile, tamper-evident sachets26. The precision and hygiene offered by these machines are critical in this field.

Personal Care and Cosmetics: Ideal for shampoos, conditioners, lotions, and cosmetic samples8. The attractive sachets are well-suited for promotional samples and travel-sized products.

Industrial Products: Effective for packaging chemicals, agrochemicals, and hardware items that require safe, durable, and well-sealed packaging8.

What Key Features Should You Look for When Choosing a Machine?

Selecting the right machine requires careful consideration of its features. The following table compares some common aspects found in different models:

Feature Importance & Example Control System PLC with touchscreen interface allows for precise control, easy setup, and storage of multiple packaging recipes for different products110. Sealing Mechanism Heated jaws with precise temperature control (often with multiple zones) ensure consistent and strong seals across different packaging materials3. Film Feeding System Servo motor-driven film transport provides accurate bag length control and smooth operation, reducing film stress and tearing15. Versatility Ability to handle various film materials (like laminates, aluminum foil, polyethylene) and accommodate a range of bag dimensions is crucial for adaptability48. Beyond these, look for features such as automatic fault diagnosis, quick-change parts for faster format adjustments, and compliance with industry safety and hygiene standards (e.g., CE certification)510.

How Do You Ensure Optimal Performance and Longevity of Your Machine?

Maximizing the return on your investment involves proper operation and maintenance. Regular cleaning of the sealing jaws is essential to prevent residue buildup that can compromise seal quality. It is also critical to use packaging materials that are compatible with the machine's sealing temperature and pressure requirements. Furthermore, scheduled maintenance checks on components like the servo motors, cutting blades, and sensors can prevent unexpected breakdowns and prolong the machine's operational life. Training operators to fully understand the machine's capabilities and control system will also enhance overall efficiency and productivity.

Conclusion

Horizontal 4-side seal sachet packaging machines represent a significant leap forward in packaging technology. They offer an unmatched combination of speed, reliability, and aesthetic quality, making them an indispensable asset for businesses aiming to scale up production and enhance product presentation. By understanding their functionality, benefits, and key selection criteria, companies can make an informed decision that drives growth and strengthens their market position.

We use our own and third-party cookies to ensure the proper functioning of the web portal and its complements, perform navigation analysis and show multimedia content. If you continue browsing, you accept the use of this technology. For more information please see our Cookies Policy

We want to constantly improve the user-friendliness and performance of our websites. For this reason we use analysis technologies (including cookies) which pseudonymously measure and evaluate which functions and content of our websites are used, how and how often. On this basis we can improve our websites for users.

Contact information:

Address: #330, Xinnuo Road, Fengxian District, Shanghai