In the world of packaging, efficiency and versatility are paramount. One of the most innovative solutions that have emerged in recent years is the doypack packaging machine. This machine is designed to fill and seal stand-up pouches, commonly known as doypacks, which have become increasingly popular in various industries, including food, beverages, cosmetics, and pharmaceuticals. In this article, we will explore what a doypack machine is, its various types, and how to choose the right packing machine for your needs.

Understanding Doypack Packaging

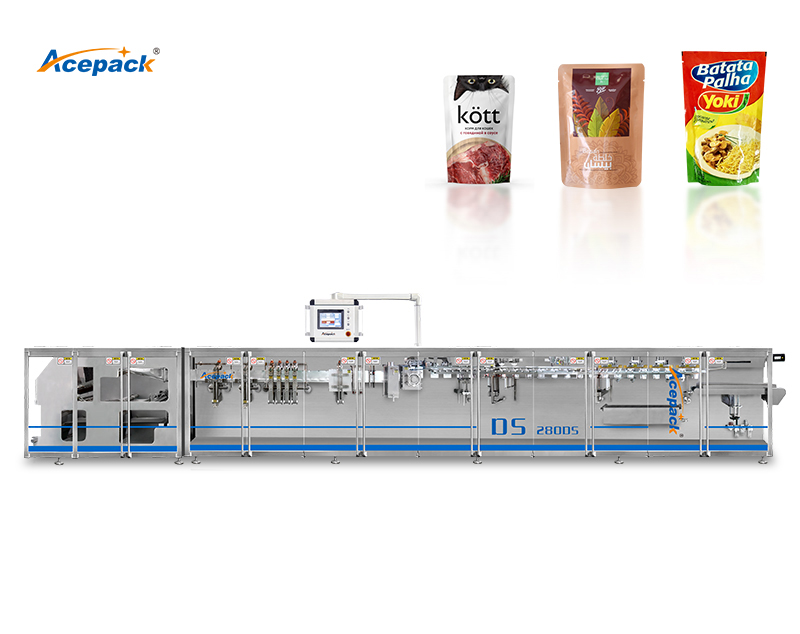

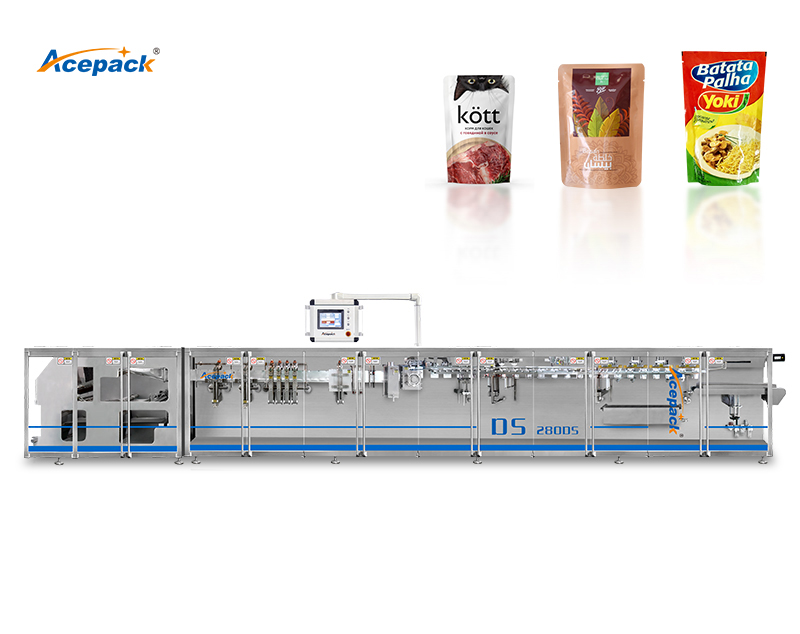

Before diving into the specifics of doypack machines, it’s essential to understand what doypack packaging is. Doypack, also known as stand-up pouch packaging, is a flexible packaging format that allows products to stand upright on shelves, making them visually appealing and easy to store. These pouches are typically made from multiple layers of materials, including plastic and aluminum, which provide excellent barrier properties to protect the contents from moisture, light, and oxygen.

Doypacks are widely used for packaging a variety of products, including snacks, liquids, powders, and even pet food. Their lightweight nature and reduced material usage compared to traditional rigid packaging make them an environmentally friendly option. Additionally, doypacks can be resealable, enhancing convenience for consumers.

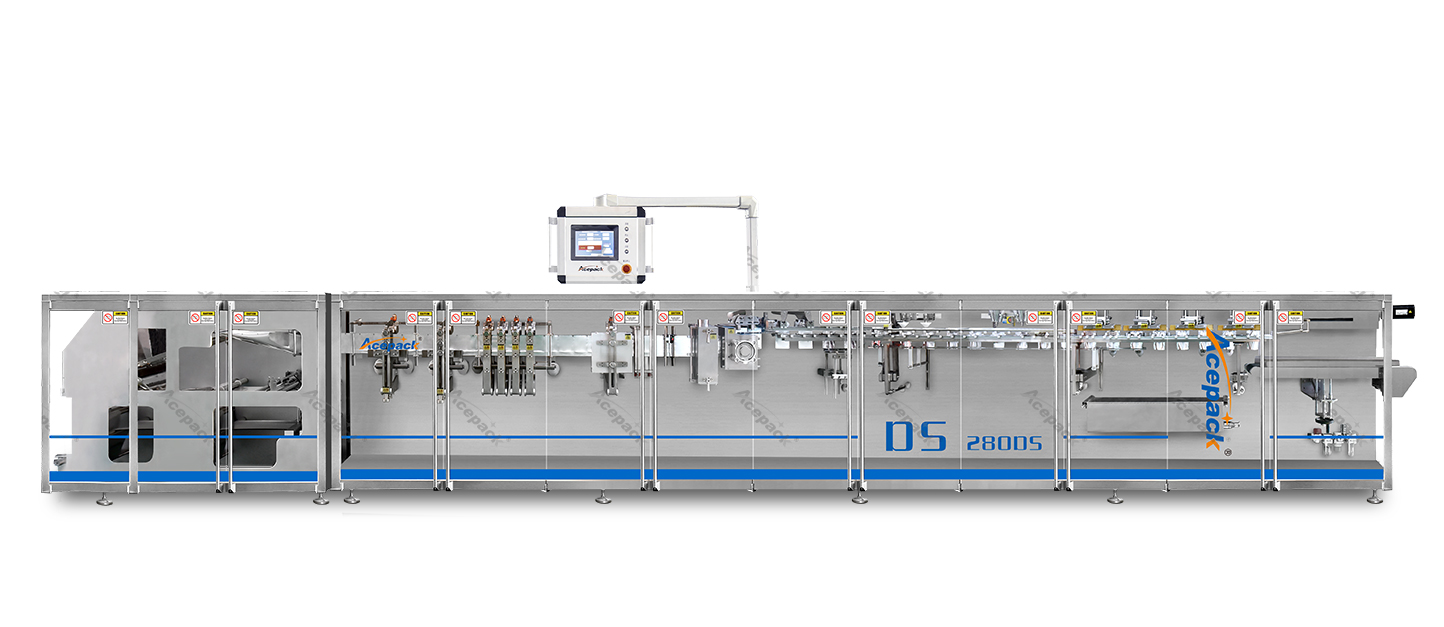

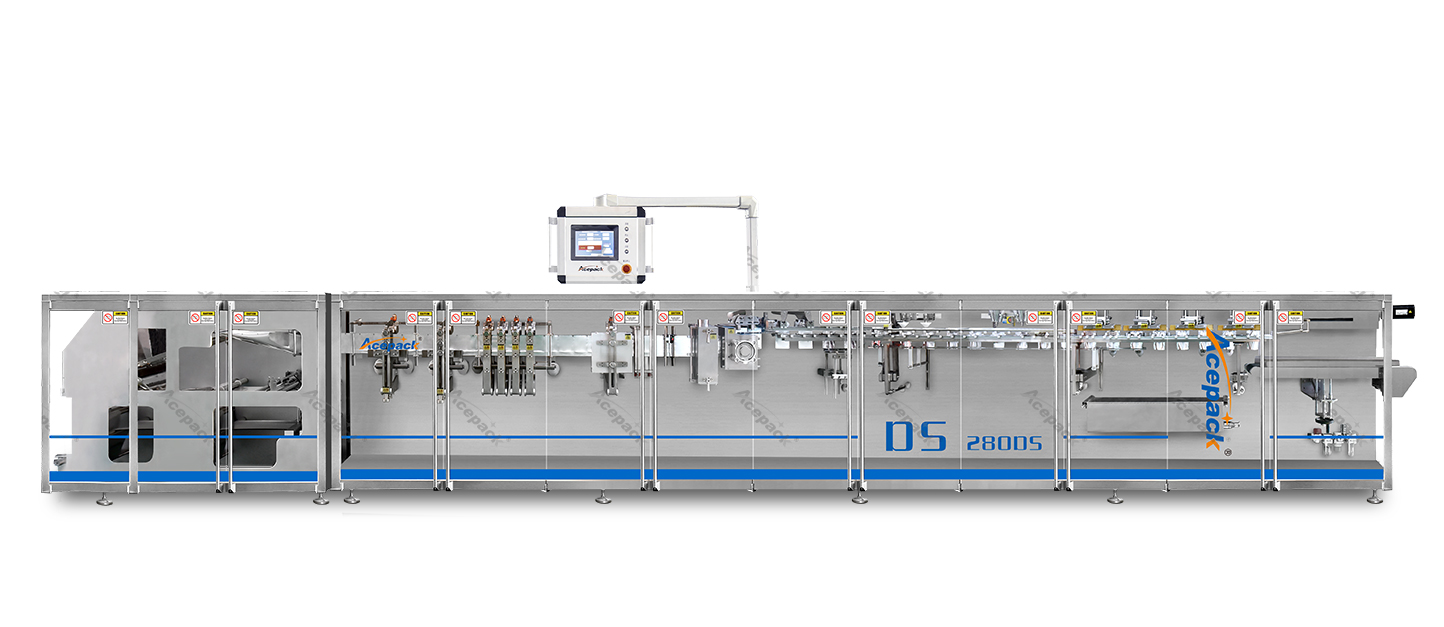

What is a Doypack Packaging Machine?

A Doypack Packaging Machine is a specialized piece of equipment designed for the filling and sealing of stand-up pouches. These machines can handle various types of products, including solids, liquids, and powders, making them highly versatile. The primary functions of a doypack machine include:

Filling: The machine accurately fills the pouches with the desired product. Depending on the type of doypack filling machine, this can be done using volumetric, gravimetric, or pump filling methods.

Sealing: After filling, the machine seals the pouches to ensure product freshness and prevent contamination. This can be achieved through heat sealing, cold sealing, or ultrasonic sealing, depending on the materials used for the pouches.

Cutting and Shaping: Some doypack machines also have the capability to cut and shape the pouches, creating a finished product that is ready for distribution.

Labeling and Printing: Advanced doypack machines may include features for labeling and printing directly on the pouches, streamlining the packaging process.

Types of Doypack Machines

There are several types of doypack machines available in the market, each designed to cater to specific packaging needs. Here are some common types:

Doypack Filling Machine: This machine focuses primarily on the filling process. It can handle various products and is often used in conjunction with a separate sealing machine.

Doypack Packing Machine: This type of machine combines both filling and sealing functions in one unit, making it a compact solution for businesses with limited space.

Stand Up Pouch Filling and Sealing Machine: This machine is designed specifically for stand-up pouches and can handle high-speed production. It is ideal for businesses looking to increase their packaging efficiency.

Automatic Doypack Machine: These machines are fully automated, allowing for minimal human intervention. They are suitable for large-scale production and can significantly reduce labor costs.

Semi-Automatic Doypack Machine: These machines require some manual input but still offer a level of automation that increases efficiency compared to fully manual processes.

How Do I Choose a Packing Machine?

Choosing the right packing machine for your business can be a daunting task, especially with the variety of options available. Here are some key factors to consider when selecting a doypack packaging machine:

1. Product Type

The first step in choosing a packing machine is to consider the type of product you will be packaging. Different machines are designed to handle specific product characteristics, such as viscosity, granule size, and flowability. For example, a doypack filling machine for liquids will differ from one designed for powders or solids.

2. Production Volume

Assess your production needs. If you have a high volume of products to package, an automatic doypack machine may be the best choice, as it can handle large quantities efficiently. Conversely, if your production volume is lower, a semi-automatic machine may suffice.

3. Pouch Size and Material

Doypacks come in various sizes and materials. Ensure that the machine you choose can accommodate the specific pouch size and material you plan to use. Some machines are adjustable and can handle multiple sizes, while others are designed for specific dimensions.

4. Sealing Method

Consider the sealing method that best suits your product and pouch material. Heat sealing is common for plastic pouches, while cold sealing may be more appropriate for sensitive products. Ensure that the machine you choose can perform the required sealing method effectively.

5. Budget

Budget is always a crucial factor in any business decision. Doypack machines can vary significantly in price, depending on their features and capabilities. Determine your budget and look for machines that offer the best value for your investment.

6. Ease of Use and Maintenance

Choose a machine that is user-friendly and easy to operate. Additionally, consider the maintenance requirements of the machine. A machine that is easy to clean and maintain will save you time and reduce downtime in your production process.

7. Supplier Reputation and Support

Finally, consider the reputation of the machine supplier. Look for manufacturers with a proven track record in the industry and positive customer reviews. Additionally, ensure that they offer adequate support and service in case you encounter any issues with the machine.

Conclusion

Doypack packaging machines have revolutionized the way products are packaged, offering versatility, efficiency, and sustainability. Understanding what a doypack machine is and the various types available can help you make an informed decision when choosing the right packing machine for your business. By considering factors such as product type, production volume, pouch size, sealing method, budget, ease of use, and supplier reputation, you can select a doypack machine that meets your specific needs and enhances your packaging process. As the demand for flexible packaging continues to grow, investing in a doypack machine can position your business for success in a competitive market.