In the fast-paced world of manufacturing and packaging, efficiency and precision are paramount. One of the most innovative solutions that have emerged in recent years is the stick packing machine. This advanced technology has revolutionized the way products are packaged, particularly in the food, pharmaceutical, and cosmetic industries. In this article, we will explore the benefits of using stick packing machines, including multilane stick packing machines and granule filling machines, as well as their various applications.

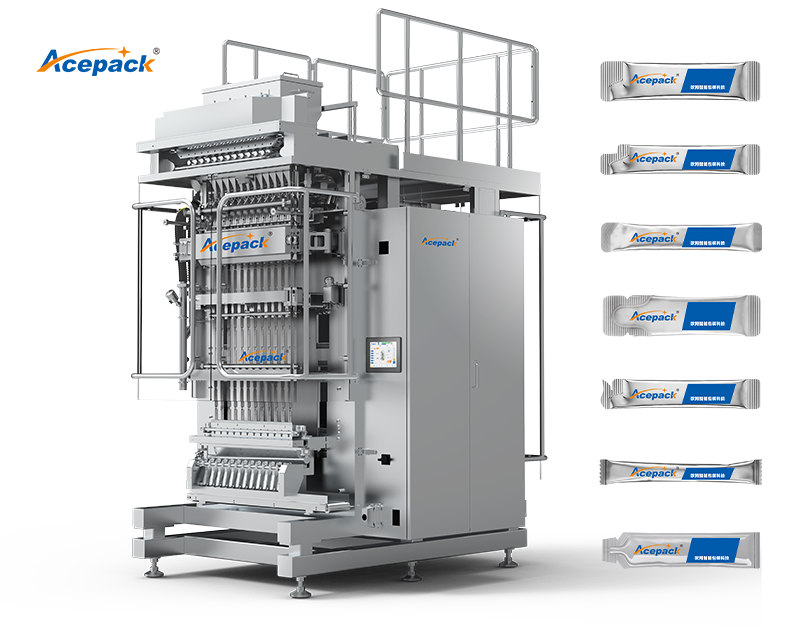

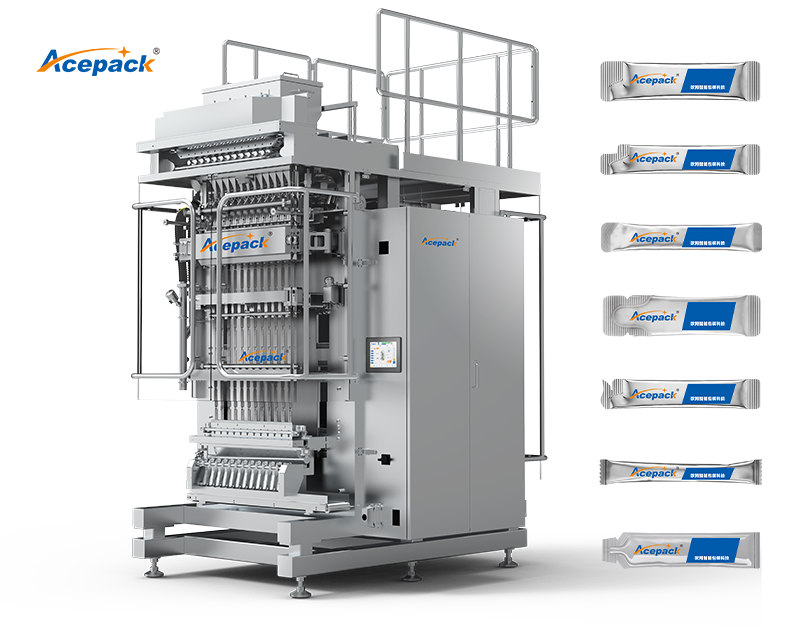

A stick packing machine is a specialized piece of equipment designed to package products into stick-shaped pouches. These machines can handle a variety of materials, including powders, granules, liquids, and pastes. The stick packs are typically made from flexible packaging materials, which can be easily sealed to ensure product freshness and integrity.

Multilane Stick Packing Machines

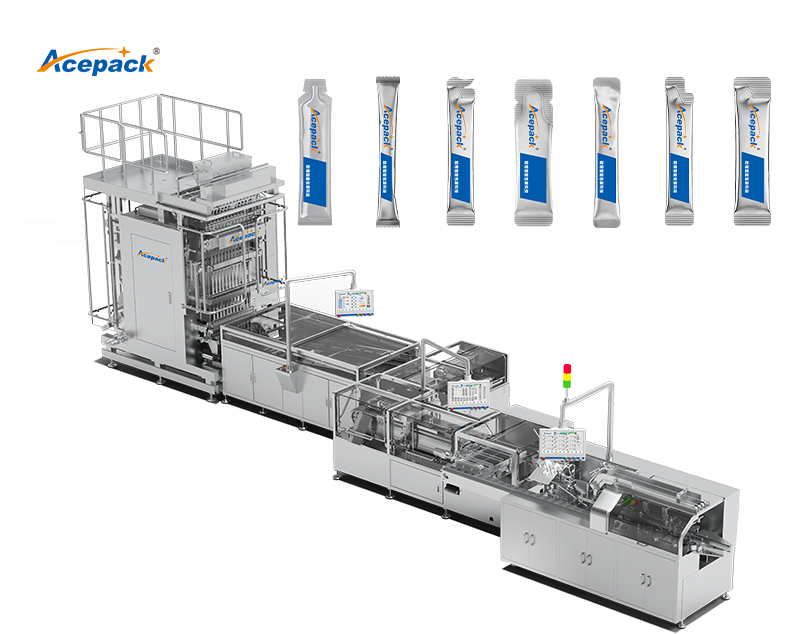

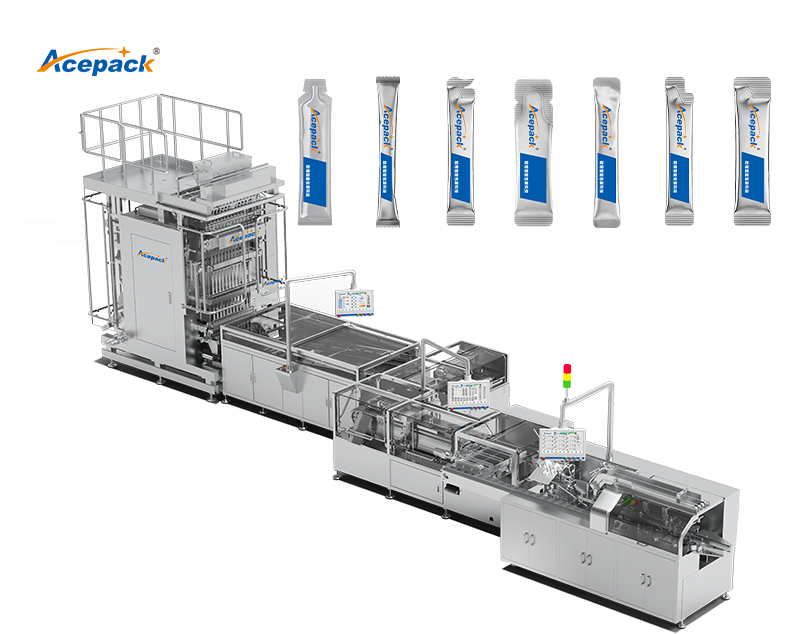

Multilane stick packing machines are an advanced version of traditional stick packing machines. They operate multiple lanes simultaneously, allowing for higher production rates and increased efficiency. This type of machine is particularly beneficial for businesses that require large volumes of packaging in a short amount of time.

Granule Filling Machines

Granule filling machines are often integrated with stick packing machines to facilitate the packaging of granular products. These machines are designed to accurately fill stick packs with granules, ensuring that each pack contains the correct amount of product. This precision is crucial for maintaining product quality and meeting regulatory standards.

Benefits of Using Stick Packing Machines

1. Increased Efficiency

One of the primary benefits of using stick packing machines is the significant increase in efficiency they offer. With the ability to package multiple lanes simultaneously, multilane stick packing machines can produce a higher output compared to traditional packaging methods. This efficiency not only speeds up the production process but also reduces labor costs, as fewer operators are needed to manage the packaging line.

2. Cost-Effectiveness

Investing in a stick packing machine can lead to substantial cost savings in the long run. The automation of the packaging process reduces the need for manual labor, which can be a significant expense for manufacturers. Additionally, stick packs are lightweight and require less material than traditional packaging, leading to lower material costs and reduced shipping expenses.

3. Versatility

Stick packing machines are incredibly versatile and can handle a wide range of products. From powdered beverages and instant coffee to granulated spices and pharmaceutical powders, these machines can accommodate various materials. This versatility makes them an ideal choice for businesses that offer multiple products or are looking to expand their product lines.

4. Enhanced Product Protection

The stick packs produced by stick packing machines provide excellent protection for the contents. The sealed pouches are resistant to moisture, air, and light, which helps to preserve the freshness and quality of the product. This is particularly important for food and pharmaceutical products, where maintaining product integrity is crucial.

5. Improved Shelf Appeal

Stick packs are not only functional but also visually appealing. The sleek design of stick packs can enhance the shelf appeal of products, making them more attractive to consumers. Additionally, the ability to print high-quality graphics and branding on the packaging allows businesses to create a strong brand presence in the market.

6. Easy to Use

Stick packs are user-friendly and convenient for consumers. The single-serving size makes them easy to carry and consume on the go, which is increasingly important in today’s fast-paced lifestyle. This convenience can lead to increased customer satisfaction and repeat purchases.

7. Compliance with Regulations

In industries such as pharmaceuticals and food, compliance with regulations is essential. Stick packing machines can be designed to meet specific industry standards, ensuring that the packaging process adheres to all necessary regulations. This compliance helps businesses avoid costly fines and maintain their reputation in the market.

Applications of Stick Packing Machines

1. Food Industry

The food industry is one of the largest users of stick packing machines. These machines are commonly used to package powdered beverages, instant coffee, sugar, salt, spices, and snack foods. The convenience of stick packs makes them popular among consumers, particularly for single-serving products.

2. Pharmaceutical Industry

In the pharmaceutical sector, stick packing machines are used to package powdered medications, supplements, and vitamins. The precise filling capabilities of granule filling machines ensure that each stick pack contains the correct dosage, which is critical for patient safety and compliance with health regulations.

3. Cosmetic Industry

The cosmetic industry has also embraced stick packing technology. Products such as powdered face masks, dry shampoos, and other beauty products can be effectively packaged in stick packs. The portability and ease of use of these packs make them appealing to consumers looking for convenient beauty solutions.

4. Chemical Industry

Stick packing machines are utilized in the chemical industry for packaging powdered chemicals, detergents, and other granular products. The ability to package these materials in a controlled and efficient manner helps to streamline production processes and improve safety.

5. Agricultural Products

In agriculture, stick packing machines can be used to package fertilizers, seeds, and other granular products. The precise filling capabilities ensure that each pack contains the correct amount of product, which is essential for effective application.

Conclusion

Stick packing machines, including multilane stick packing machines and granule filling machines, offer numerous benefits that can significantly enhance the efficiency and effectiveness of packaging operations. Their versatility, cost-effectiveness, and ability to improve product protection make them an invaluable asset for businesses across various industries. As consumer demand for convenient and high-quality packaging continues to grow, the adoption of stick packing technology is likely to increase, paving the way for further innovations in the packaging sector. Whether in the food, pharmaceutical, cosmetic, or chemical industries, stick packing machines are poised to play a crucial role in the future of packaging.