In the fast-paced world of manufacturing and packaging, efficiency and precision are paramount. One of the most innovative solutions that have emerged in recent years is the automatic premade pouch packing machine. But what exactly is this machine, and how does it transform the packaging process for various industries? In this blog, we will explore the features, benefits, and applications of automatic premade pouch packing machines, shedding light on their significance in modern packaging.

What is an Automatic Premade Pouch Packing Machine?

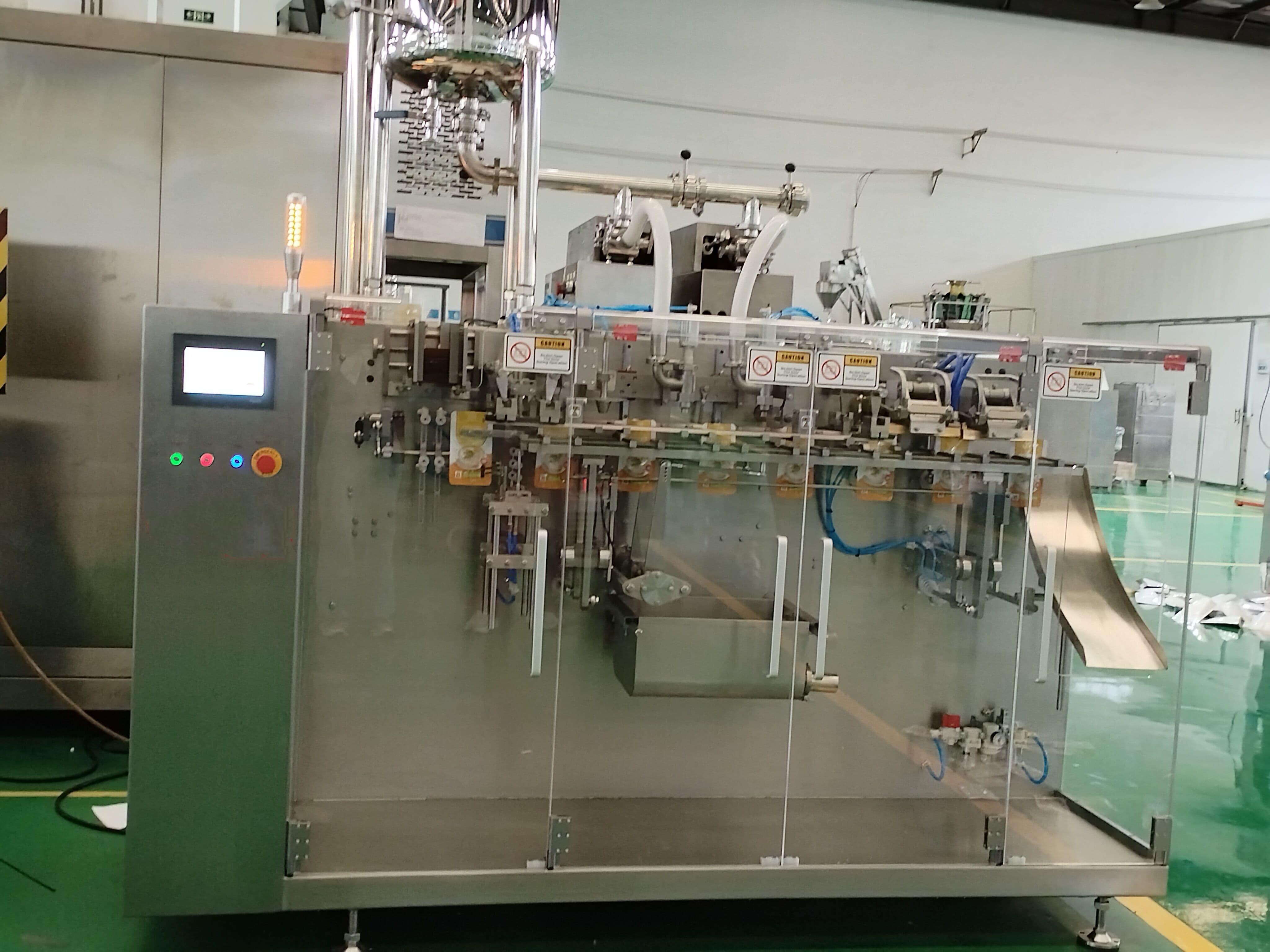

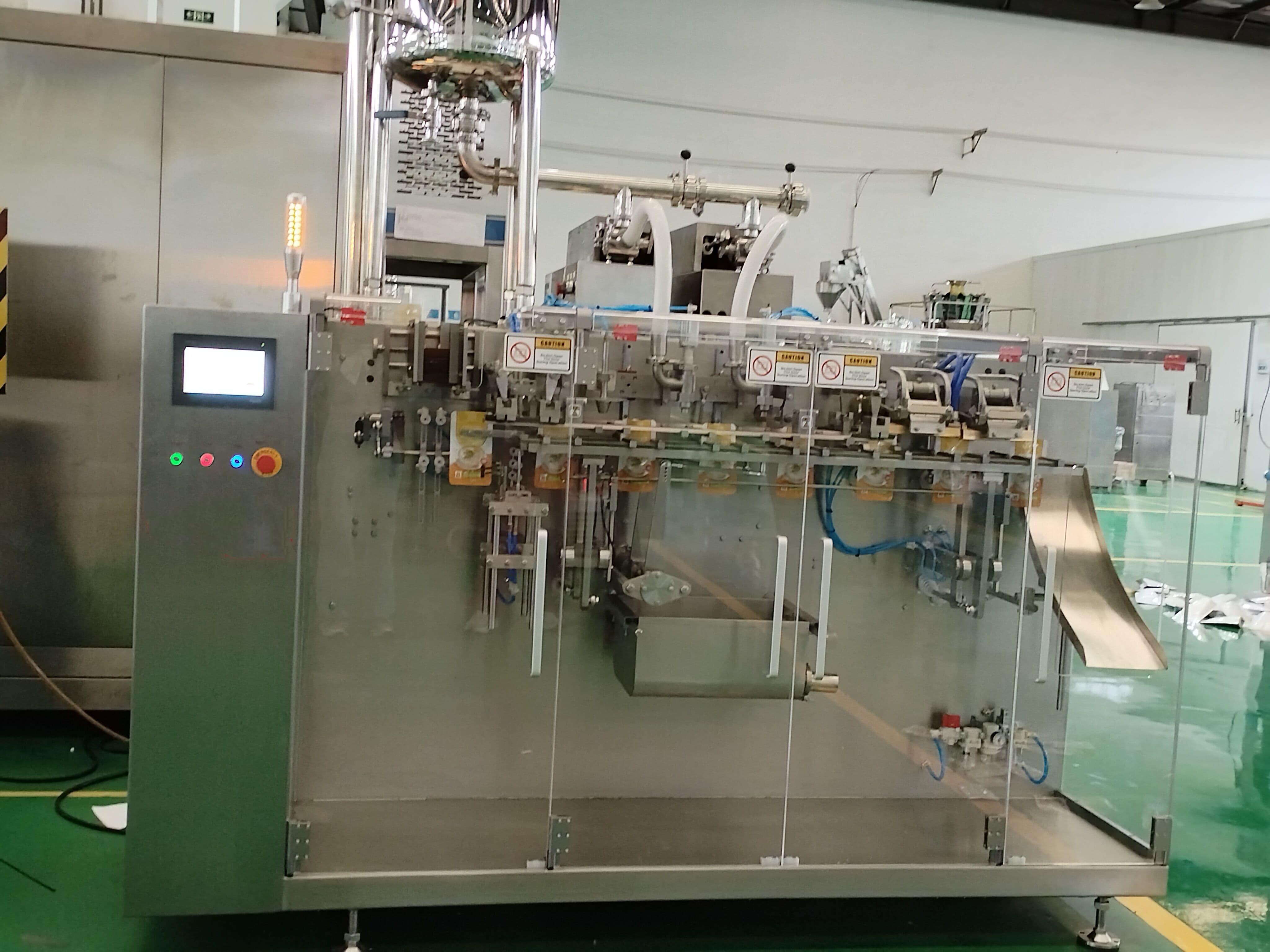

An automatic premade pouch packing machine is a sophisticated piece of equipment designed to fill and seal pre-made pouches with various products. Unlike traditional packaging methods that require the creation of pouches on-site, this machine utilizes pre-manufactured pouches, which can be made from a variety of materials, including plastic, foil, and paper. The machine automates the entire process, from pouch feeding to filling and sealing, ensuring high efficiency and consistency.

How Does It Work?

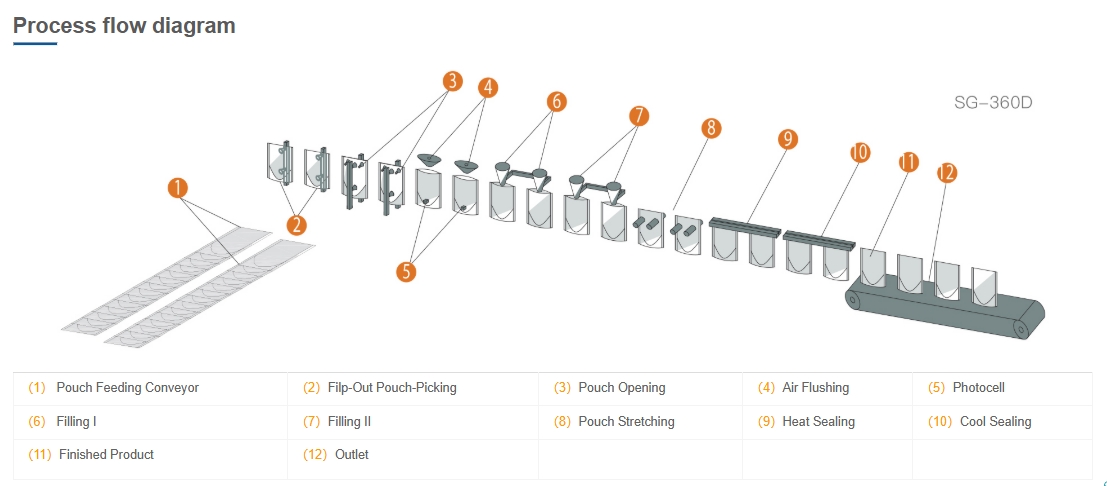

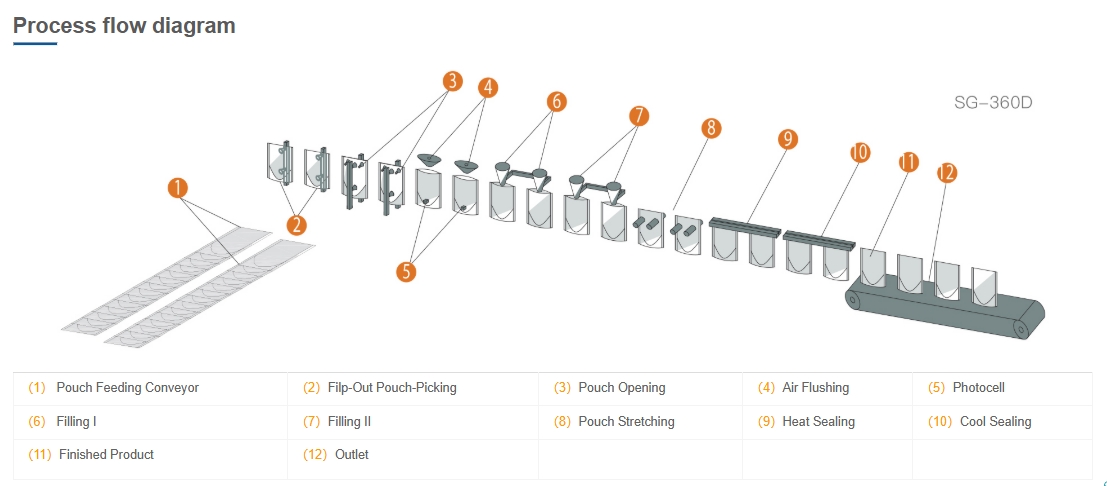

The operation of an automatic premade pouch packing machine can be broken down into several key steps:

Pouch Feeding: The machine is equipped with a feeder that automatically loads the pre-made pouches into the packing area. This process eliminates the need for manual handling, reducing labor costs and increasing speed.

Pouch Opening: Once the pouches are fed into the machine, they are opened using a series of mechanical arms or vacuum systems. This ensures that the pouches are ready to be filled without any damage.

Filling: After the pouches are opened, the machine fills them with the desired product. This can include powders, granules, liquids, or even solid items. The filling process is highly accurate, ensuring that each pouch contains the correct amount of product.

Sealing: Once filled, the pouches are sealed using heat or pressure, depending on the material. This step is crucial for maintaining product freshness and preventing contamination.

Cutting and Discharge: Finally, the machine cuts the pouches if necessary and discharges them for further processing or packaging.

What Are the Benefits of Using an Automatic Premade Pouch Packing Machine?

The adoption of automatic premade pouch packing machines offers numerous advantages for businesses across various sectors:

Increased Efficiency: By automating the packaging process, companies can significantly increase their production rates. This is particularly beneficial for businesses that require high-volume packaging, such as food and beverage manufacturers.

Cost Savings: While the initial investment in an automatic packing machine may be substantial, the long-term savings in labor costs and material waste can be significant. Automation reduces the need for manual labor and minimizes errors, leading to lower operational costs.

Consistency and Quality: Automatic machines provide a level of precision that is difficult to achieve with manual packaging. This consistency ensures that each pouch is filled and sealed to the same high standard, enhancing product quality and customer satisfaction.

Versatility: Automatic premade pouch packing machines can handle a wide range of products and pouch sizes. This versatility makes them suitable for various industries, including food, pharmaceuticals, cosmetics, and more.

Improved Hygiene: In industries where hygiene is critical, such as food and pharmaceuticals, automatic machines reduce the risk of contamination. With minimal human contact during the packaging process, the likelihood of introducing contaminants is significantly lowered.

How Are Automatic Premade Pouch Packing Machines Used in Different Industries?

The versatility of automatic premade pouch packing machines allows them to be utilized in various sectors, each with unique packaging requirements:

Food Industry: In the food sector, these machines are commonly used for packaging snacks, sauces, powders, and ready-to-eat meals. The ability to create airtight seals ensures product freshness and extends shelf life.

Pharmaceuticals: The pharmaceutical industry relies on automatic pouch packing machines for packaging tablets, capsules, and powders. The precision and hygiene offered by these machines are essential for maintaining product integrity.

Cosmetics: Cosmetic products, such as creams and serums, are often packaged in premade pouches. The automatic machines provide an efficient way to fill and seal these products while maintaining a high level of quality.

Pet Food: The pet food industry has also embraced automatic premade pouch packing machines for packaging kibble, treats, and wet food. The ability to handle various pouch sizes and materials makes these machines ideal for diverse product lines.

What Should You Consider When Choosing an Automatic Premade Pouch Packing Machine?

When selecting an automatic premade pouch packing machine, several factors should be taken into account:

Product Type: Consider the type of product you will be packaging. Different machines are designed for specific products, so ensure that the machine you choose is compatible with your product’s characteristics.

Pouch Size and Material: Evaluate the sizes and materials of the pouches you plan to use. Some machines are more versatile than others, so choose one that can accommodate your requirements.

Production Speed: Determine your production needs and select a machine that can meet your desired output. Higher-speed machines may be necessary for high-volume operations.

Budget: While investing in an automatic packing machine can lead to long-term savings, it’s essential to consider your budget and the potential return on investment.

Maintenance and Support: Look for machines that come with reliable customer support and easy maintenance options. This will ensure that your machine remains operational and efficient over time.

Conclusion

In conclusion, automatic premade pouch packing machines are revolutionizing the packaging industry by offering increased efficiency, cost savings, and improved product quality. Their versatility allows them to be used across various sectors, making them an invaluable asset for businesses looking to enhance their packaging processes. By understanding what these machines are and how they work, companies can make informed decisions that will ultimately lead to greater success in their packaging endeavors.