In the fast-paced world of food production and packaging, efficiency and convenience are paramount. One of the innovations that have significantly transformed the way condiments, particularly ketchup, are packaged is the ketchup sachet packing machine. But what exactly is this machine, and how does it work? In this blog, we will explore the intricacies of ketchup sachet packing machines, their benefits, and their impact on the food industry.

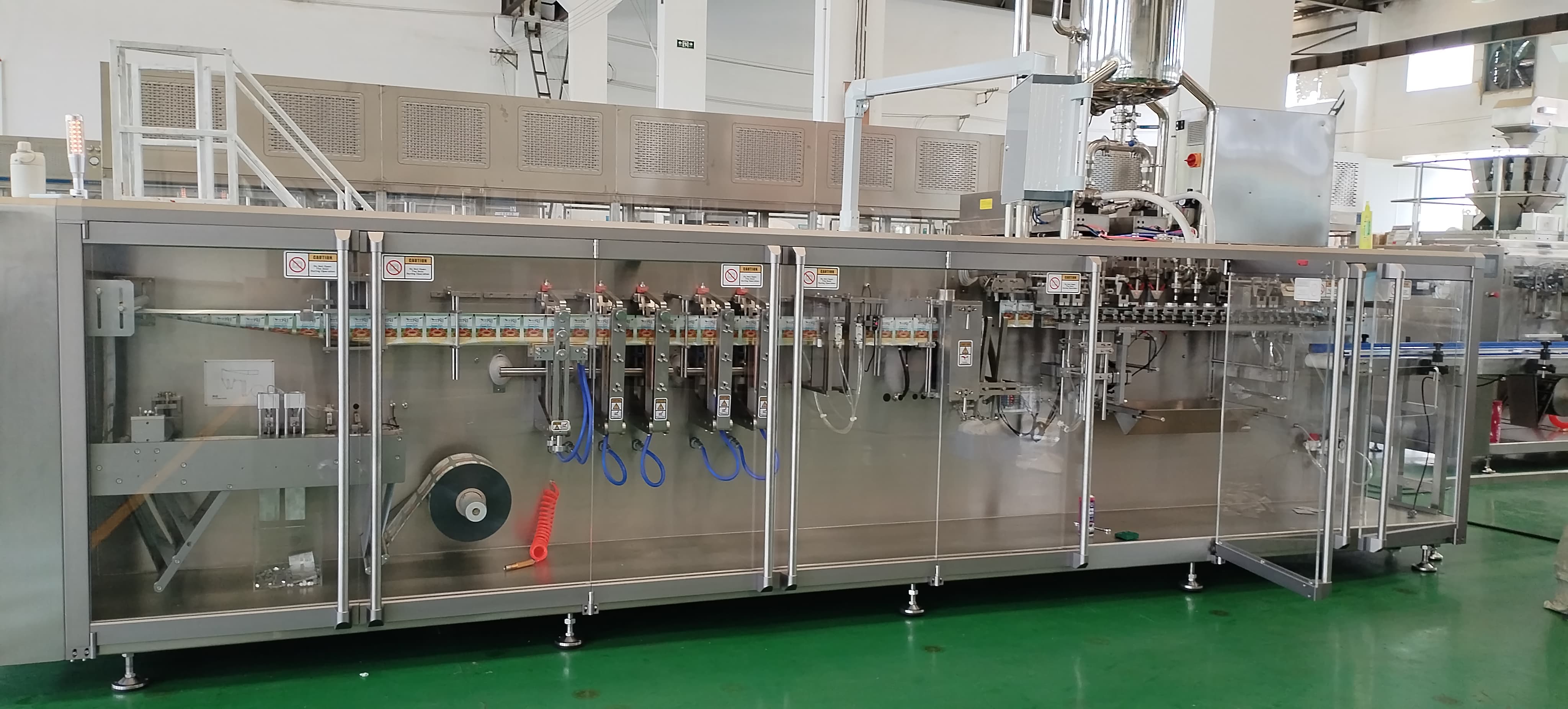

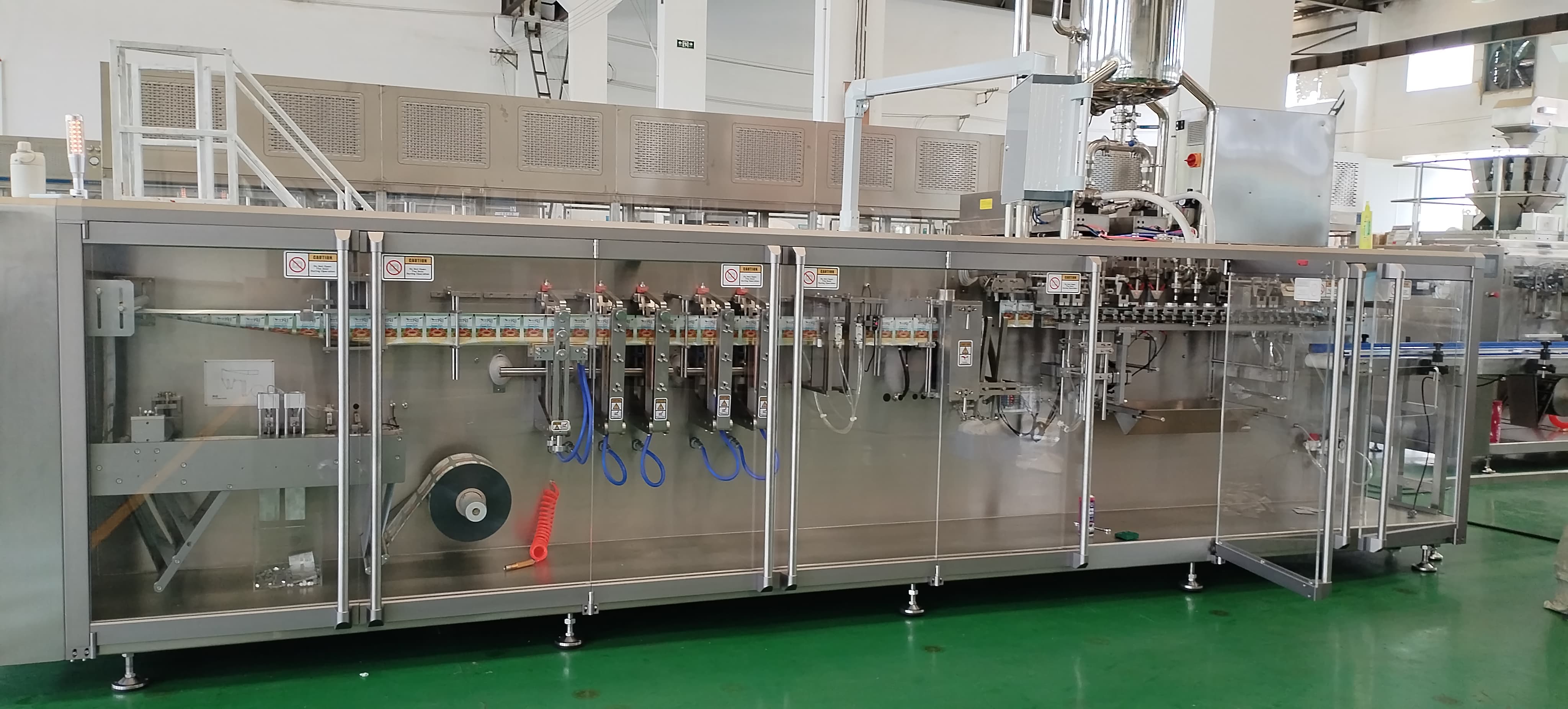

A ketchup sachet packing machine is a specialized piece of equipment designed to fill and seal ketchup into small, single-serving sachets. These sachets are typically made from flexible materials that are easy to open and consume, making them ideal for fast-food restaurants, food trucks, and convenience stores. The machine automates the entire process, from filling the sachets with ketchup to sealing them securely, ensuring that the product remains fresh and uncontaminated.

How Does a Ketchup Sachet Packing Machine Work?

The operation of a ketchup sachet packing machine can be broken down into several key steps:

Material Feeding: The machine is equipped with a hopper that holds the ketchup. The ketchup is fed into the machine from this hopper, ensuring a continuous supply for the sachet filling process.

Sachet Formation: The machine uses rolls of flexible packaging material to create sachets. The material is unwound and formed into a tube, which is then cut to the desired length to create individual sachets.

Filling: Once the sachet is formed, the machine fills it with a precise amount of ketchup. This is done using a volumetric or gravimetric filling system, which ensures that each sachet contains the same amount of product, maintaining consistency and quality.

Sealing: After filling, the sachet is sealed using heat or pressure. This step is crucial as it prevents leakage and contamination, ensuring that the ketchup remains fresh until it is opened by the consumer.

Cutting and Discharge: Finally, the machine cuts the sachets apart and discharges them for packaging or distribution. Some machines also include features for labeling or printing expiration dates directly onto the sachets.

Why is a Ketchup Sachet Packing Machine Important?

The importance of ketchup sachet packing machines in the food industry cannot be overstated. Here are several reasons why they are essential:

Efficiency: These machines significantly speed up the packaging process compared to manual methods. They can produce thousands of sachets per hour, allowing businesses to meet high demand without sacrificing quality.

Cost-Effectiveness: By automating the packaging process, companies can reduce labor costs and minimize waste. The precision of the filling process also ensures that there is little to no product loss, further enhancing profitability.

Convenience: Ketchup sachets are incredibly convenient for consumers. They are easy to carry, require no refrigeration, and can be used on-the-go, making them a popular choice for fast-food establishments and events.

Hygiene and Safety: The automated nature of the ketchup sachet packing machine reduces the risk of contamination that can occur with manual handling. The sealed sachets also protect the product from external factors, ensuring safety and hygiene.

Customization: Many modern ketchup sachet packing machines offer customization options, allowing businesses to create sachets in various sizes, shapes, and designs. This flexibility can help brands stand out in a competitive market.

What are the Challenges of Using a Ketchup Sachet Packing Machine?

While ketchup sachet packing machines offer numerous benefits, there are also challenges that businesses may face:

Initial Investment: The cost of purchasing and installing a ketchup sachet packing machine can be significant. However, many companies view this as a long-term investment that will pay off through increased efficiency and reduced labor costs.

Maintenance: Like any machinery, ketchup sachet packing machines require regular maintenance to ensure optimal performance. This can involve routine checks, cleaning, and occasional repairs, which can be time-consuming.

Training: Employees need to be trained to operate the machine effectively. This training can take time and resources, but it is essential for maximizing the machine’s potential.

How is the Future of Ketchup Sachet Packing Machines Shaping Up?

As technology continues to advance, the future of ketchup sachet packing machines looks promising. Innovations such as smart technology, which allows for real-time monitoring and adjustments, are becoming more common. Additionally, the growing demand for sustainable packaging solutions is prompting manufacturers to develop eco-friendly sachet materials, which could further enhance the appeal of ketchup sachets.

Conclusion

In conclusion, ketchup sachet packing machines are a vital component of the modern food packaging industry. They offer efficiency, cost-effectiveness, and convenience, making them an attractive option for businesses looking to streamline their operations. As technology continues to evolve, we can expect these machines to become even more advanced, further revolutionizing the way we package and consume our favorite condiments. Whether you are a small food vendor or a large-scale manufacturer, investing in a ketchup sachet packing machine could be a game-changer for your business.