In the world of packaging, efficiency and precision are paramount. Have you ever wondered how machines for packing standy pouches, commonly known as doypack pouches, operate? What makes these machines essential in various industries, from food to cosmetics? In this blog, we will explore the intricate workings of these packaging machines, their benefits, and the technology behind them.

What Are Doypack Pouches?

Before delving into the operation of packing machines, it’s crucial to understand what doypack pouches are. What distinguishes a doypack from other types of packaging? Doypack pouches are flexible, stand-up pouches that can hold a variety of products, including liquids, powders, and granules. Their unique design allows them to stand upright on shelves, making them visually appealing and space-efficient. But how are these pouches filled and sealed?

How Do Packing Machines Work?

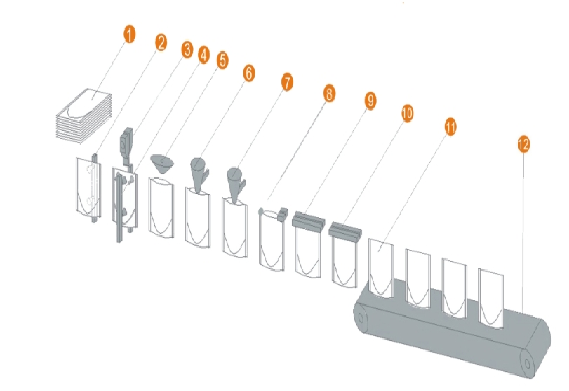

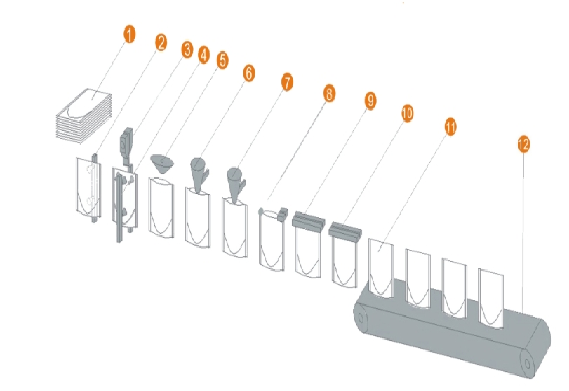

What is the first step in the operation of a machine designed for packing standy pouches? The process typically begins with the feeding of empty pouches into the machine. But how does the machine ensure that the pouches are correctly aligned and ready for filling? Most modern machines are equipped with sensors and automated systems that detect the position of each pouch, ensuring that they are fed into the filling station without any jams or misalignments.

Once the pouches are in place, how does the filling process occur? The machine uses a filling nozzle that dispenses the product into the pouch. What types of products can these machines handle? From liquids like sauces and juices to dry goods like snacks and powders, the versatility of these machines is impressive. But how do they maintain accuracy during the filling process? Many machines are equipped with volumetric or gravimetric filling systems that ensure each pouch receives the exact amount of product required.

What Happens After Filling?

After the pouches are filled, what is the next step in the packaging process? The filled pouches then move to the sealing station. How does the machine seal the pouches to ensure freshness and prevent leakage? Most machines utilize heat sealing technology, where the top of the pouch is heated and pressed together to create a secure seal. But what if the product inside is sensitive to heat? In such cases, machines may use cold sealing methods or other specialized techniques to ensure the integrity of the product.

How Are Doypack Pouches Customized?

What if a company wants to customize their doypack pouches? Can the packaging machine accommodate different sizes and designs? Yes, many modern packing machines are designed to be flexible and can handle various pouch sizes and styles. Operators can easily adjust the machine settings to switch between different pouch formats, making it a cost-effective solution for businesses that offer multiple products.

Why should businesses invest in machines for packing standy pouches? The benefits are numerous. First and foremost, these machines significantly increase production speed. How does this impact a business’s bottom line? By automating the packaging process, companies can produce more pouches in less time, reducing labor costs and increasing efficiency.

Additionally, what about the consistency and quality of the packaging? Machines ensure that each pouch is filled and sealed uniformly, which is crucial for maintaining product quality and brand reputation. How does this affect consumer trust? When customers receive products in well-packaged pouches, they are more likely to trust the brand and make repeat purchases.

How Do Packing Machines Contribute to Sustainability?

In today’s environmentally conscious market, how do machines for packing standy pouches contribute to sustainability? Many manufacturers are now producing pouches from recyclable or biodegradable materials. What role do packing machines play in this? By using these sustainable materials, companies can reduce their environmental footprint while still benefiting from the efficiency of automated packaging.

What Are the Future Trends in Doypack Packaging?

As technology continues to evolve, what does the future hold for machines that pack doypack pouches? Innovations such as smart packaging and IoT integration are on the rise. How will these advancements change the packaging landscape? Smart machines can monitor production in real-time, providing valuable data that can help optimize processes and reduce waste.

In conclusion, machines for packing standy pouches, or doypack pouches, play a vital role in modern packaging operations. What have we learned about their operation? From the initial feeding of empty pouches to the precise filling and sealing processes, these machines are designed for efficiency and accuracy. As businesses continue to seek ways to improve their packaging processes, investing in advanced packing machines will undoubtedly remain a key strategy.

So, the next time you see a doypack pouch on the shelf, you might just appreciate the intricate technology and processes that went into its packaging. What are your thoughts on the future of doypack packaging? Are you ready to embrace the innovations that lie ahead?