In the world of packaging, efficiency and versatility are key. Have you ever wondered how businesses manage to package their products so quickly and effectively? The answer often lies in the machinery they use. Two popular types of machines that have gained traction in recent years are the granule doypack packing machine and the horizontal doypack pouch packing machine. But what exactly are these machines, and how do they benefit manufacturers? Let’s dive deeper into their functionalities and advantages.

A granule doypack packing machine is specifically designed for packaging granular products. This could include anything from sugar and salt to coffee and pet food. But how does it work? Typically, the machine uses a combination of gravity and mechanical systems to fill pouches with the desired amount of granules. The pouches are then sealed, often using heat, to ensure that the contents remain fresh and uncontaminated.

How Does a Horizontal Doypack Pouch Packing Machine Operate?

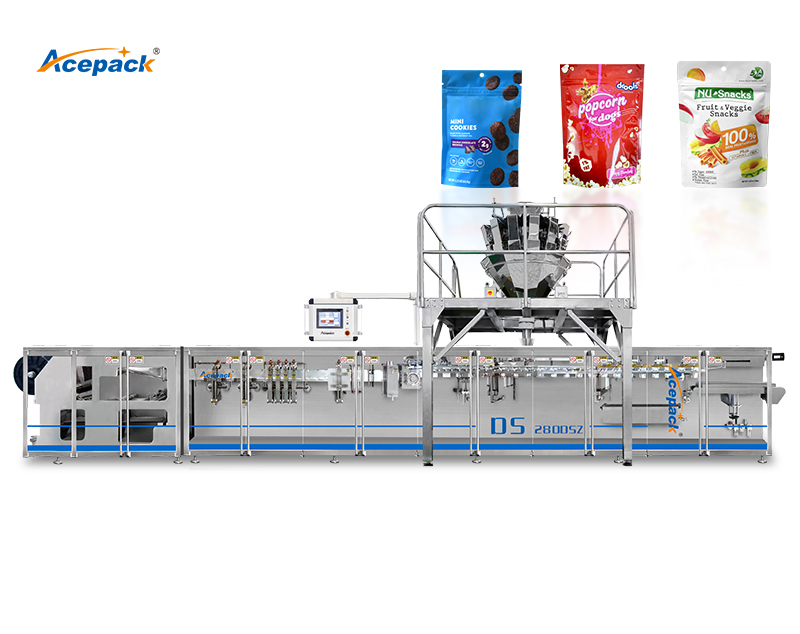

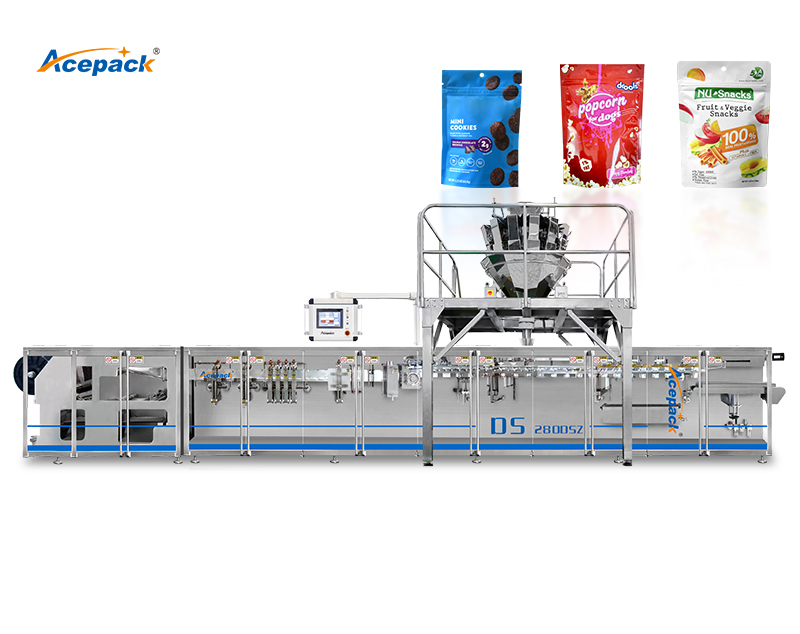

On the other hand, a horizontal doypack pouch packing machine is designed to fill and seal pouches in a horizontal orientation. This machine is versatile and can handle a variety of products, including liquids, powders, and granules. But what makes it different from the granule doypack packing machine? The horizontal design allows for a more streamlined process, as products can be fed into the machine from the side, making it easier to integrate into existing production lines.

What Are the Key Features of These Machines?

Both machines come equipped with several features that enhance their functionality. For instance, many granule doypack packing machines include adjustable filling nozzles, which allow for precise measurement of the product being packaged. This is crucial for maintaining consistency and ensuring that each pouch contains the correct amount of product.

Similarly, horizontal doypack pouch packing machines often feature advanced control systems that allow operators to monitor and adjust the filling process in real-time. This can lead to increased efficiency and reduced waste, as operators can quickly identify and rectify any issues that arise during production.

How Do These Machines Improve Efficiency?

One of the most significant benefits of using a granule doypack packing machine or a horizontal doypack pouch packing machine is the increase in efficiency. But how do they achieve this? By automating the packaging process, these machines can significantly reduce the time it takes to package products. This means that businesses can produce more in less time, ultimately leading to higher profits.

Moreover, the precision offered by these machines minimizes the risk of overfilling or underfilling pouches, which can lead to product loss and increased costs. With accurate filling, businesses can ensure that they are getting the most out of their materials.

What Are the Cost Benefits?

Investing in a granule doypack packing machine or a horizontal doypack pouch packing machine can also lead to significant cost savings. But what are the specific financial benefits? First, the automation of the packaging process reduces labor costs, as fewer workers are needed to operate the machinery. Additionally, the reduction in product waste due to precise filling can lead to lower material costs over time.

Furthermore, these machines are often designed to be energy-efficient, which can lead to lower utility bills. When considering the long-term savings, the initial investment in these machines can pay off quickly.

How Do These Machines Enhance Product Quality?

Another important aspect to consider is the impact of these machines on product quality. But how do they contribute to maintaining high standards? The sealing mechanisms used in both types of machines are designed to create airtight seals, which help to preserve the freshness and quality of the product inside. This is particularly important for products that are sensitive to moisture or air exposure.

Additionally, the use of high-quality materials in the construction of these machines ensures that they can withstand the rigors of daily use, leading to fewer breakdowns and maintenance issues. This reliability translates to consistent product quality, which is essential for maintaining customer satisfaction.

What Industries Benefit fromThese Machines?

The versatility of granule doypack packing machines and horizontal doypack pouch packing machines means that they can be used across various industries. But which industries benefit the most? Food and beverage manufacturers often rely on these machines for packaging items like snacks, spices, and beverages. Similarly, the pharmaceutical industry uses them for packaging powders and granules.

Moreover, the pet food industry has also seen a rise in the use of these machines, as they can efficiently package a variety of pet food products. The ability to customize pouches for different products makes these machines an attractive option for businesses in any sector.

Conclusion: Are These Machines Right for Your Business?

In conclusion, the granule doypack packing machine and the horizontal doypack pouch packing machine offer numerous benefits that can enhance efficiency, reduce costs, and improve product quality. But are they the right choice for your business? If you’re looking to streamline your packaging process and increase your production capabilities, investing in one of these machines could be a game-changer.

As you consider your options, think about the specific needs of your business and how these machines can help you meet your goals. With the right equipment, you can take your packaging operations to the next level and stay competitive in today’s fast-paced market.