Required web technologies and cookies make our website technically accessible to and usable for you. This applies to fundamental base functionalities such as navigation on the website, correct display in your internet browser or requesting your consent. Without these web technologies and cookies our website does not work.

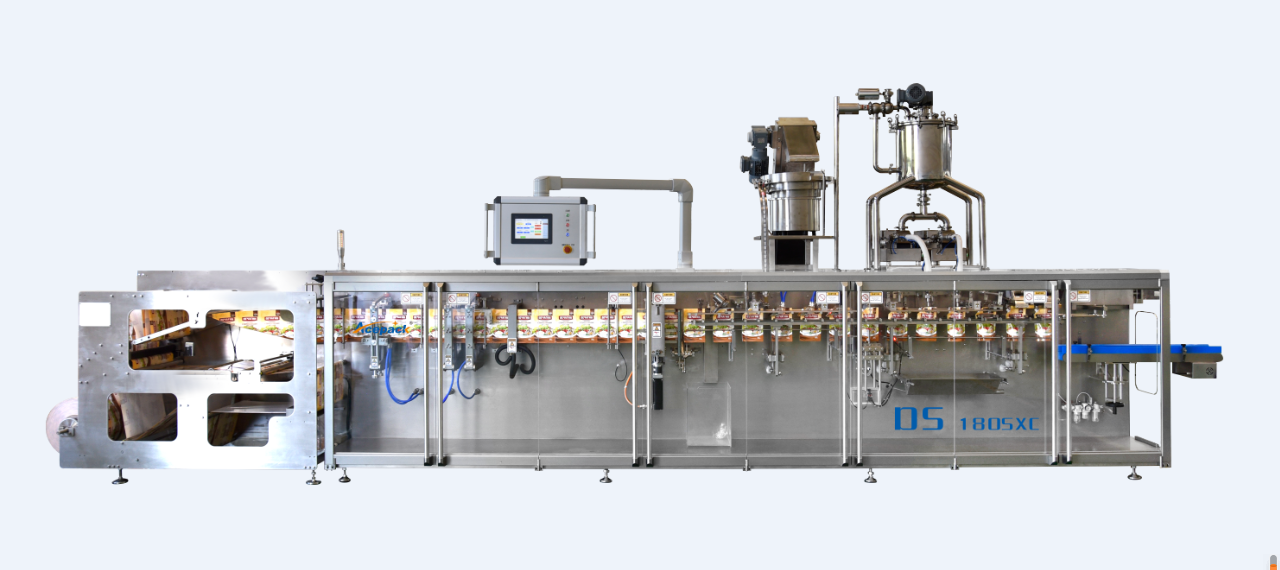

Mayonnaise Spout Pouch Packaging Machine for Viscous Products

High efficiency mayonnaise spout pouch packaging machine with precise filling for viscous products durable design and easy operation

Key Product Highlights

The Mayonnaise Spout Pouch Packaging Machine is purpose-built for efficient, hygienic, and precise packaging of viscous products like mayonnaise and other creamy condiments. Designed for food manufacturers aiming to boost productivity and maintain consistent quality, this machine integrates advanced technology with user-friendly operation.

· Specialized Viscous Filling Technology – Engineered specifically for thick products, ensuring smooth flow without clogging or mess.

· Precision Filling System – Volumetric or piston filling options provide consistent portion control for every pouch.

· Fully Automatic Operation – Forms pouches, attaches spouts, fills, and seals in a single seamless process.

· Customizable Pouch Options – Handles multiple pouch sizes and spout types to fit your branding and production needs.

· Food Grade Stainless Steel – Built with hygienic 304 stainless steel, meeting strict food safety and sanitation standards.

· Touch Screen Control – Simple PLC interface with programmable parameters for easy adjustments and recipe storage.

· Energy Efficient Design – Low power consumption with minimal downtime for maximum operational efficiency.

· Optional Multi-Lane Configuration – Scale up production speeds with dual or multiple filling lanes.

· Quality Control Sensors – Integrated detection ensures accuracy, seal integrity, and eliminates reject waste.

· Dedicated Support – Backed by ACEPACK’s expert service team for installation, training, and after-sales assistance.

Product Description

The mayonnaise spout pouch packaging machine is built to handle thick, creamy products with ease. Its specialized filling system is designed to manage the unique texture of mayonnaise without clogging or air gaps. The fully automatic setup takes care of forming the pouch, attaching the spout, filling, and sealing in one continuous process, keeping production fast and consistent.

It delivers airtight, hygienic packaging that locks in freshness and extends shelf life while making the product convenient for consumers. The machine is constructed from food-grade 304 stainless steel, meeting strict U.S. food safety standards and making cleanup simple.

With its intuitive touch-screen controls, you can dial in the exact fill volume and pouch size for each run—whether you’re producing small batches for specialty orders or scaling up for high-volume production. This flexibility makes it an ideal fit for U.S. condiment manufacturers who need both efficiency and quality in their packaging lines.

Technical Specifications for the Mayonnaise Spout Pouch Packaging Machine

Here’s a quick look at the core specs so you know exactly what this equipment can handle:

| Specification | Details |

| Machine Type | Fully automatic spout pouch packaging machine |

| Filling Method | Piston or peristaltic pump |

| Filling Volume Range | 50ml – 500ml (customizable) |

| Pouch Size Range | Width: 80–150mm / Length: 120–250mm |

| Filling Speed | Up to 30 pouches per minute |

| Spout Type Options | Screw cap or flip top |

| Material | 304 food-grade stainless steel |

| Power Supply | 220V or 380V, 50/60Hz |

| Machine Dimensions | Customizable to fit production space |

| Control System | PLC with color touch screen interface |

Designed for thick sauces like mayonnaise, ketchup, and other condiments, this spout pouch filling machine delivers accurate fills, steady speeds, and consistent seal quality. The PLC touch screen controls make it easy to adjust settings for different pouch sizes, fill volumes, or spout styles, making it a reliable solution for U.S. food producers needing both efficiency and flexibility.

Features and Benefits of the Mayonnaise Spout Pouch Packaging Machine

Our mayonnaise spout pouch packaging machine is built to handle thick, viscous products while keeping operations smooth, safe, and cost‑efficient. Here’s what makes it stand out:

Built for Viscous Products

Perfectly fills mayonnaise, sauces, syrups, and other thick liquids.

- Delivers a clean, consistent pouch presentation without mess or dripping.

Food Safety First

- 304 food‑grade stainless steel frame for complete hygiene.

- Automated cleaning functions to save time and maintain high sanitation standards.

Flexible Packaging Options

- Works with various pouch sizes and spout types (screw caps, flip‑tops, etc.).

- Easy to switch between products without long setup times.

High Efficiency

- Fast changeovers to minimize downtime.

- Maintains steady filling speed with minimal waste.

Cost Control

- Reduces material waste through precise filling.

- Energy‑efficient design lowers operating costs over time.

Smart Monitoring

- Real‑time data tracking and quality checks.

- Built‑in error alarms to catch issues early.

Strong After‑Sales Support

- Installation and operator training included.

- Remote support and quick response service across the U.S.

Applications

The mayonnaise spout pouch packaging machine works for a lot more than just mayonnaise. It’s built to handle thick, creamy, or sticky products without mess or waste, making it a solid choice for many industries.

Food Products:

- Mayonnaise – Clean, precise filling for retail or foodservice pouches.

- Ketchup and sauces – Keeps viscosity consistent with accurate portion control.

- Yogurt and dairy desserts – Airtight seal for freshness and extended shelf life.

- Honey and syrups – Non-drip, smooth dispensing to reduce waste.

- Creams and spreads – Nut butters, cheese spreads, and similar products fill easily.

Non-Food Options:

- Cosmetic creams or lotions – Keeps product protected and easy to dispense.

- Pharmaceutical creams and gels – Fills hygienically to meet safety needs.

If you package any viscous or semi-liquid product, especially in spouted pouches, this machine can handle it with speed and precision. It helps businesses cut down on manual labor, maintain consistency, and improve shelf appeal.

Why Choose ACEPACK

When it comes to spout pouch packaging machines for mayonnaise and other thick condiments, ACEPACK stands out for a few key reasons that matter to U.S. producers.

Proven Innovation in Viscous Product Packaging

We design machines specifically for challenging products like mayonnaise, ketchup, and sauces. Our filling technology handles thick textures without mess or waste, giving you a clean, consistent pouch every time.

Experience That Works for You

With years of working alongside condiment manufacturers around the world, including brands in the United States, we understand the real-world demands of both small-batch craft kitchens and large-scale production lines.

Quality and Reliability You Can Count On

Our machines are built with food-grade 304 stainless steel, designed to meet strict safety standards. Each unit is engineered for long-term durability and low maintenance.

Designed for Heavy Use

Robust construction means our machines keep running with minimal downtime––critical for meeting high-volume orders without delays.

Global Service and Local Support

We offer service coverage worldwide, with remote technical help, on-site training, and quick turnaround on spare parts for U.S. customers.

| ACEPACK Advantage | What It Means for You |

| Purpose-built viscous filling | Clean, precise pouches for thick products |

| Global industry experience | Proven solutions that fit your production needs |

| Stainless steel build | FDA-compliant, hygienic, and long-life construction |

| Robust engineering | Reliable performance for heavy-duty production |

| Worldwide service network | Localized support and faster problem resolution |

Customer Testimonials or Case Studies

One of our long-time customers, the CEO of a mid-sized mayonnaise brand in the Midwest, shared how our mayonnaise spout pouch packaging machine transformed their production line.

“Before switching to the ACEPACK automatic spout pouch filler, we were constantly dealing with inconsistent fill levels and frequent downtime. Now, our output is faster, the fill is precise every time, and we’ve cut our packa

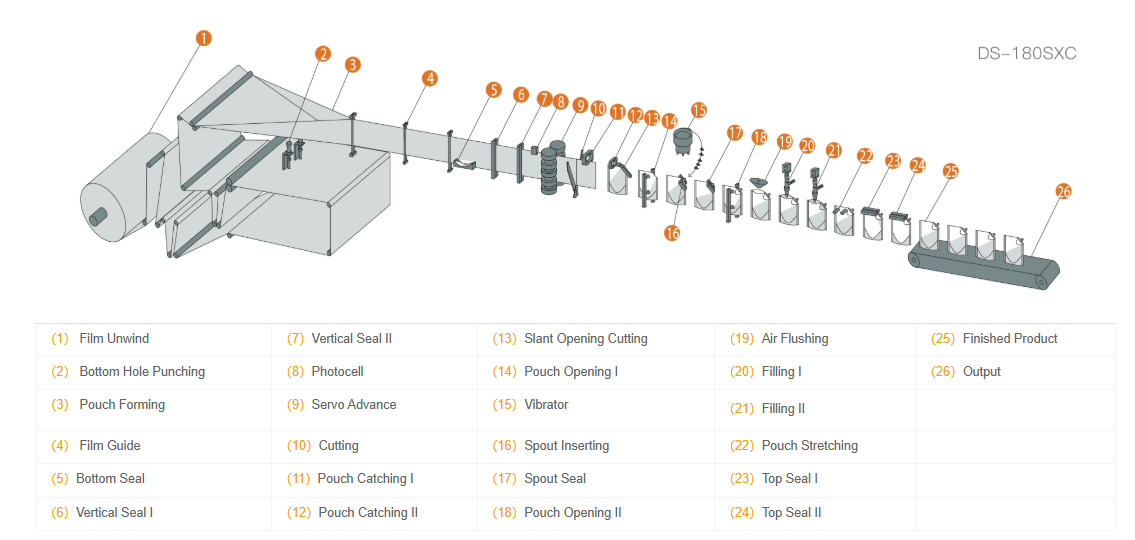

How it work?

FEEDBACK FORM CONTACT WITH US

Please leave us message for your inquiry: