Required web technologies and cookies make our website technically accessible to and usable for you. This applies to fundamental base functionalities such as navigation on the website, correct display in your internet browser or requesting your consent. Without these web technologies and cookies our website does not work.

Welcome to visit Acepack website

Service Hotline:+8618017198917

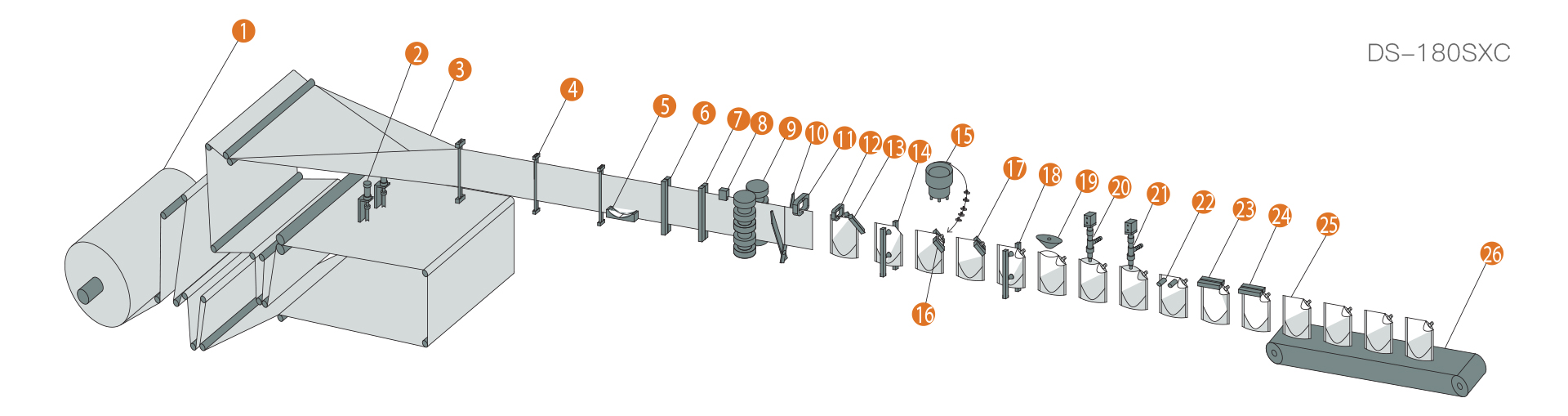

Corner Spout stand pouch filling machine

*Full-servo double-out roll film design can save 30%-50% of packaging costs

*The design of adding the mouth first and then filling, the suction nozzle is pollution-free and compatible with the filling of pulp particles *The independent sealing design of the suction nozzle can avoid deformation and damage caused by capping

*Easy to clean, easy to maintain, easy to maintain, stable and durable

*It can be operated by one person without manual threading of the bag pole, which greatly reduces labor costs

Product parameters

| Model | DS-180SXC |

DS-240SXC |

DS-280DSXC |

| Maximum Packing Volume | 1200ml |

2000ml |

800ml |

| Max Pouch Size | 180*260mm |

240*350mm |

140*260mm |

| Min Pouch Size | 110*120mm |

110*180mm |

110*120mm |

| Packing Speed | 40-60ppm |

30-60ppm |

80-120ppm |

| Air Consumption | 250NL/min |

350NL/min |

800NL/min |

|

Input Power | 9kw |

11kw |

13.2Kw |

| Working Power Supply | AC 380V 50Hz |

AC 380V 50Hz | AC 380V 50Hz |

| Equipment Weight | 2500kg |

3000kg |

5250kg |

| L*W*H | 6970*1100*1400mm | 7900*1250*1550mm | 9400*1500*1800mm |

| (1) Film Unwind | (7)Vertical Seal II |

(13)Slant Opening Cutting |

(19)Air Flushing | (25)Finished Product |

| (2) Bottom Hole Punching | (8)Photocell |

(14)Pouch Opening I |

(20)Filling I | (26)Output |

| (3) Pouch Forming | (9)Servo Advance |

(15)Vibrator |

(21)Filling II | |

| (4) Film Guide | (10)Cutting |

(16)Spout Inserting |

(22)Pouch Stretching | |

| (5)Bottom Seal | (11)Pouch Catching I |

(17)Spout Seal |

(23)Top Seal I | |

| (6)Vertical Seal I | (12)Pouch Catching II | (18)Pouch Opening II | (24)Top Seal II |

FEEDBACK FORM CONTACT WITH US

Please leave us message for your inquiry: