The Precision Engineering Behind Perfect Packaging

In the world of food manufacturing, packaging is applied science. For a product as delicate and complex as mayonnaise, the choice of packaging machinery is a decision that impacts product quality, operational efficiency, and ultimately, profitability. A standard liquid packager cannot handle the specific rheology and preservation needs of mayo. This guide is designed for operations managers, engineers, and business owners looking to understand the technical intricacies of selecting the ideal spout pouch packaging machine for mayonnaise. We will explore the critical engineering features that separate a adequate machine from an exceptional one.

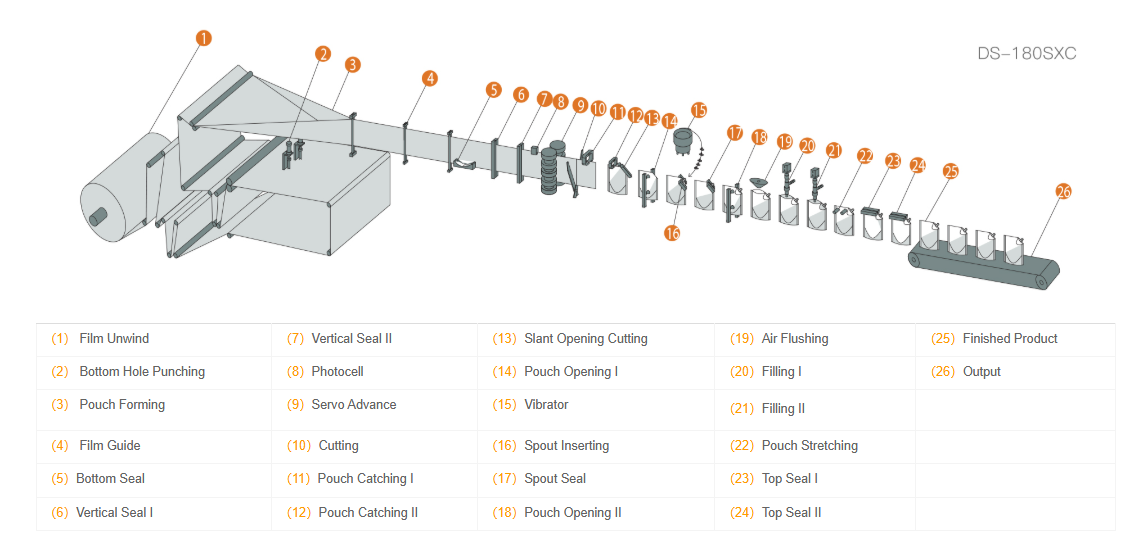

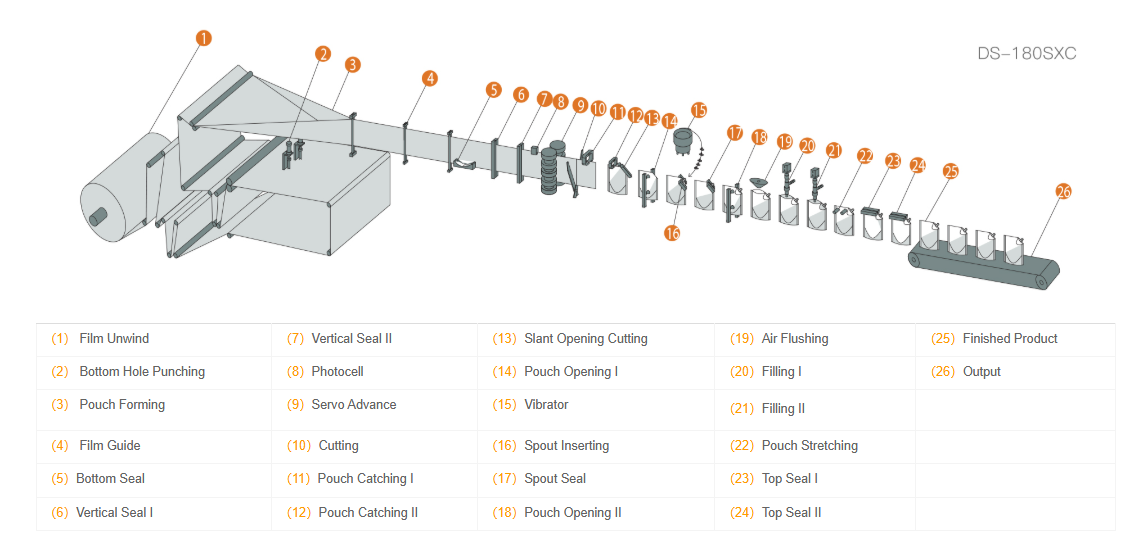

Deconstructing the Machine: Core Components and Their Function

A modern spout pouch machine is a symphony of coordinated components. For mayonnaise applications, each part must be optimized:

Pouch Denesting and Feeding System: Gently and reliably separates pre-made spout pouches from a stack and positions them for filling. Precision here prevents jams and misalignments that can halt production.

Pouch Opening and Gas Flushing Station: Mayonnaise is prone to oxidation. A key station uses gentle puffs of air to open the pouch, immediately followed by nitrogen gas flushing (N2). This inert gas displaces oxygen inside the pouch, drastically reducing oxidative rancidity and significantly extending shelf life.

The Heart of the Operation: The Filling System. This is the most critical component for mayonnaise.

Piston Fillers: Ideal for viscous products with particulates (like chipotle mayo). They provide highly accurate volumetric fills by drawing product into a cylinder and then pushing it out into the pouch. They are easy to clean and validate.

Auger Fillers: Excellent for very thick, homogeneous products. A rotating auger screw within a tube meters the product based on the number of revolutions, offering great accuracy for products that don't flow easily.

Our machines are calibrated to handle mayonnaise's viscosity, preventing air entrapment and ensuring every pouch receives the exact same weight, complying with stringent regulatory standards.

Capping Application: Automatically places and tightens the screw cap or flip-top onto the spout. Torque control is essential to ensure the cap is secure without being so tight that consumers struggle to open it.

Top and Bottom Sealing Jaws: After filling and capping, the top of the pouch must be hermetically sealed. Thermally controlled sealing jaws apply precise heat and pressure to fuse the inner laminate layers together, creating a tamper-evident and leak-proof seal that is stronger than the material itself.

Key Technical Specifications to Scrutinize

When evaluating a spout pouch packaging machine for mayonnaise, go beyond the sales brochure. Demand details on these specs:

Filling Accuracy: Look for a deviation of ±0.5% or better. This directly protects your profit margins.

Production Speed: Measured in pouches per minute (PPM). Determine your required output and choose a machine that can meet it with a comfortable buffer.

Changeover Time: How long does it take to switch from one pouch size to another? Quick-change parts and recipe-driven controls are vital for flexible manufacturing.

Hygienic Design: Insist on 316L stainless steel surfaces, sloped frames to avoid dirt traps, and compatibility with Clean-in-Place (CIP) systems. This is non-negotiable for product safety.

Integration Capabilities: The machine should seamlessly integrate with upstream (mixing tanks) and downstream (cartoning, case packing) equipment via modern PLC controls and industry-standard communication protocols (e.g., OPC UA, Ethernet/IP).

Future-Proofing Your Investment: Trends to Consider

The mayonnaise market continues to innovate. Your machine should be ready for:

Sustainable Materials: The rise of recyclable and bio-based pouch films. Ensure your machine's sealing jaws can effectively seal these new, often more challenging, materials.

Smart Manufacturing (Industry 4.0): Choose a machine with IoT capabilities for predictive maintenance, real-time OEE (Overall Equipment Effectiveness) monitoring, and remote diagnostics. This data is invaluable for optimizing production and minimizing downtime.

Product Diversification: The same machine should be adaptable to package not just classic mayo, but also lighter dressings, aiolis, and other viscous condiments, allowing you to explore new market segments.

Conclusion: Precision, Protection, and Performance

Selecting a spout pouch packaging machine for mayonnaise is a strategic technical decision. It requires a deep understanding of your product's characteristics, your production goals, and the evolving market landscape. By prioritizing precision filling, robust sealing, hygienic design, and future-ready technology, you invest in more than a machine—you invest in the reliability, quality, and growth potential of your brand.

Partner with a packaging solutions provider who speaks your technical language. Contact us to discuss your application and receive a detailed technical proposal tailored to your mayonnaise production requirements.