HFFS stands for Horizontal Form Fill Seal machines. These machines are commonly used in the packaging industry, including for products like tomato ketchup. HFFS machines automate the process of forming, filling, and sealing packages, which can enhance efficiency and reduce labor costs.

In the context of tomato ketchup, an HFFS machine would typically perform the following functions:

1. Forming: The machine creates a pouch or container from a roll of flexible packaging material. This can be done by folding and sealing the material to create the desired shape.

2. Filling: Once the pouch is formed, the machine fills it with the tomato ketchup. This is done using a filling nozzle that dispenses the precise amount of ketchup into each pouch.

3. Sealing: After filling, the machine seals the pouch to ensure that it is airtight and tamper-proof. This is crucial for maintaining the freshness and shelf life of the ketchup.

HFFS machines are favored for their speed and efficiency, making them suitable for high-volume production environments. They can handle various types of packaging materials and are often adjustable to accommodate different pouch sizes and shapes. Wtat is the key components of HFFS machines used for packaging tomato ketchup?

The key components of HFFS (Horizontal Form Fill Seal) machines used for packaging tomato ketchup include:

1. Film Unwinder: This component holds and feeds the roll of flexible packaging film into the machine. It ensures a smooth and continuous supply of film for pouch formation.

2.Forming Station: This section of the machine shapes the flat film into a pouch. It typically includes forming plates or molds that fold and seal the film to create the desired pouch shape.

3. Filling System: This component is responsible for dispensing the tomato ketchup into the formed pouches. It may include volumetric or weight-based filling mechanisms to ensure accurate portioning.

4. Sealing System: After filling, the sealing system closes the pouches. This can involve heat sealing, ultrasonic sealing, or other methods to create airtight seals that preserve the product's freshness.

5. Cutting Mechanism: This component cuts the filled and sealed pouches from the continuous film roll, creating individual packages ready for distribution.

6. Control Panel: The control panel allows operators to monitor and adjust machine settings, such as speed, temperature, and filling volume. It often includes a user-friendly interface for easy operation.

7. Conveyor System: A conveyor may be integrated into the machine to transport the filled and sealed pouches to the next stage of packaging or labeling.

8. Safety Features: HFFS machines are equipped with various safety mechanisms to protect operators and ensure safe operation, including emergency stop buttons and safety guards.

9. Product Detection Sensors: These sensors help ensure that the filling and sealing processes are performed correctly, detecting any issues such as missing pouches or incorrect fill levels.

These components work together to create an efficient and automated packaging process for tomato ketchup, ensuring high-quality, consistent, and safe packaging.

Why HFFS machines is used for ketchup?

HFFS (Horizontal Form Fill Seal) machines are used for packaging tomato ketchup for several reasons:

1. Efficiency: HFFS machines can operate at high speeds, allowing for the rapid production of pouches. This is essential for meeting the demands of large-scale ketchup production and distribution.

2. Automation: These machines automate the entire packaging process, reducing the need for manual labor. This not only lowers labor costs but also minimizes the risk of human error during packaging.

3. Versatility: HFFS machines can handle various types of flexible packaging materials, allowing manufacturers to choose the best option for their ketchup products. They can also accommodate different pouch sizes and shapes, which is beneficial for branding and marketing.

4. Sealing Quality: The sealing process in HFFS machines ensures that the pouches are airtight and tamper-proof, which is crucial for preserving the freshness and shelf life of tomato ketchup. Proper sealing also helps prevent contamination.

5. Cost-Effectiveness: By streamlining the packaging process and reducing material waste, HFFS machines can help lower overall production costs, making it more economical for manufacturers to package ketchup.

6. Product Protection: The packaging created by HFFS machines can provide excellent protection against external factors such as moisture, light, and air, which can degrade the quality of the ketchup.

7. Consumer Convenience: HFFS machines can produce pouches that are easy to use and store, catering to consumer preferences for convenience in packaging.

Overall, the use of HFFS machines for tomato ketchup packaging enhances production efficiency, product quality, and consumer satisfaction.

Case

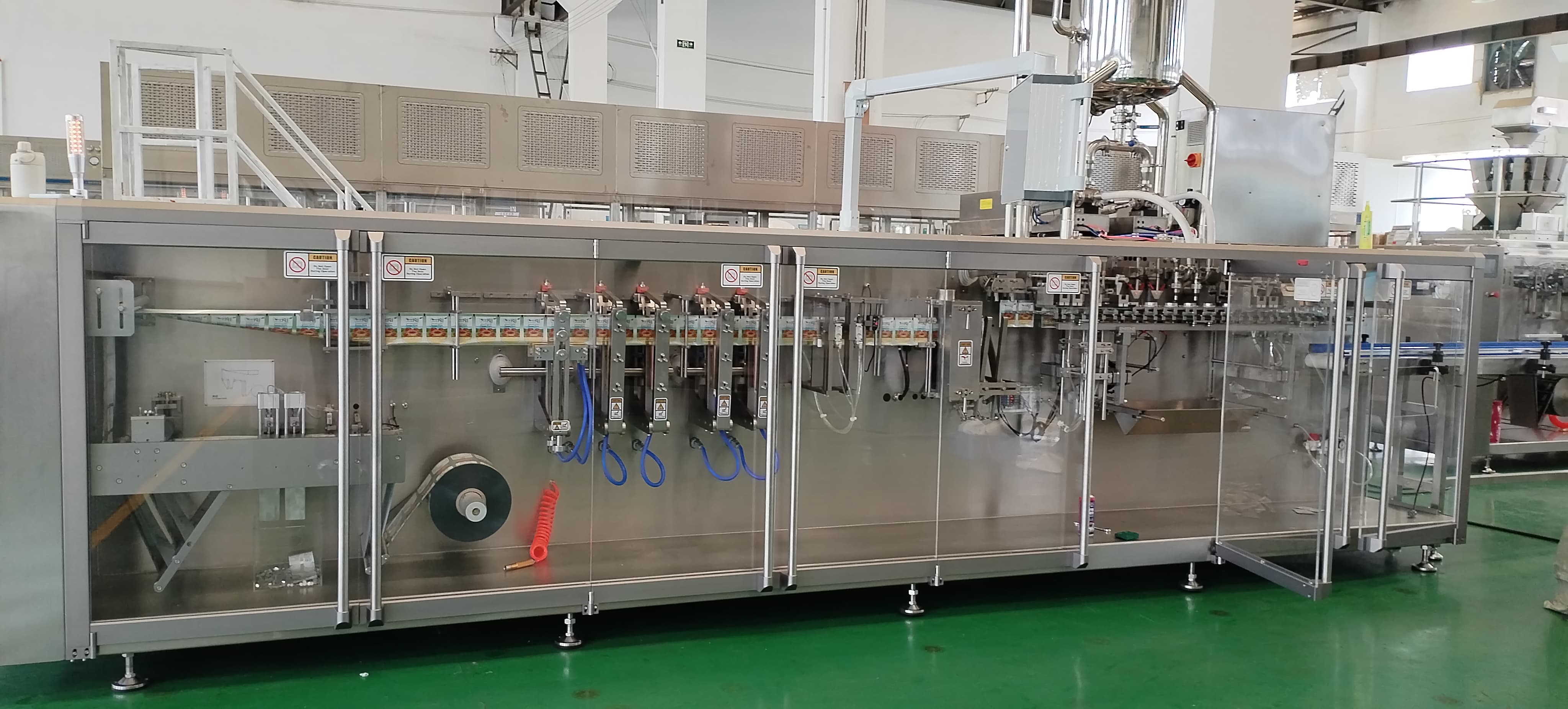

DS-180DS HFFS machines for tomato ketchup