How Does Multi-Lane 4 Side Sealing Packaging Machine Work?

来源/作者:

Shanghai Acepack Intelligent Technology Co., LTD|How Does Multi-Lane 4 Side Sealing Packaging Machine Work?

|

发布时间:

2025-08-13

|

421次浏览

|

分享到:

The multi-lane 4 side sealing packaging machine operates through a series of coordinated steps that

The multi-lane 4 side sealing packaging machine operates through a series of coordinated steps that automate the packaging process. Here’s a breakdown of how it typically works:

1. Product Feeding:

- Automatic Feeding: Products are fed into the machine, often using a conveyor system. Depending on the design, products can be fed in bulk or individually.

- Multi-Lane Configuration: The machine is designed with multiple lanes, allowing several products to be processed simultaneously.

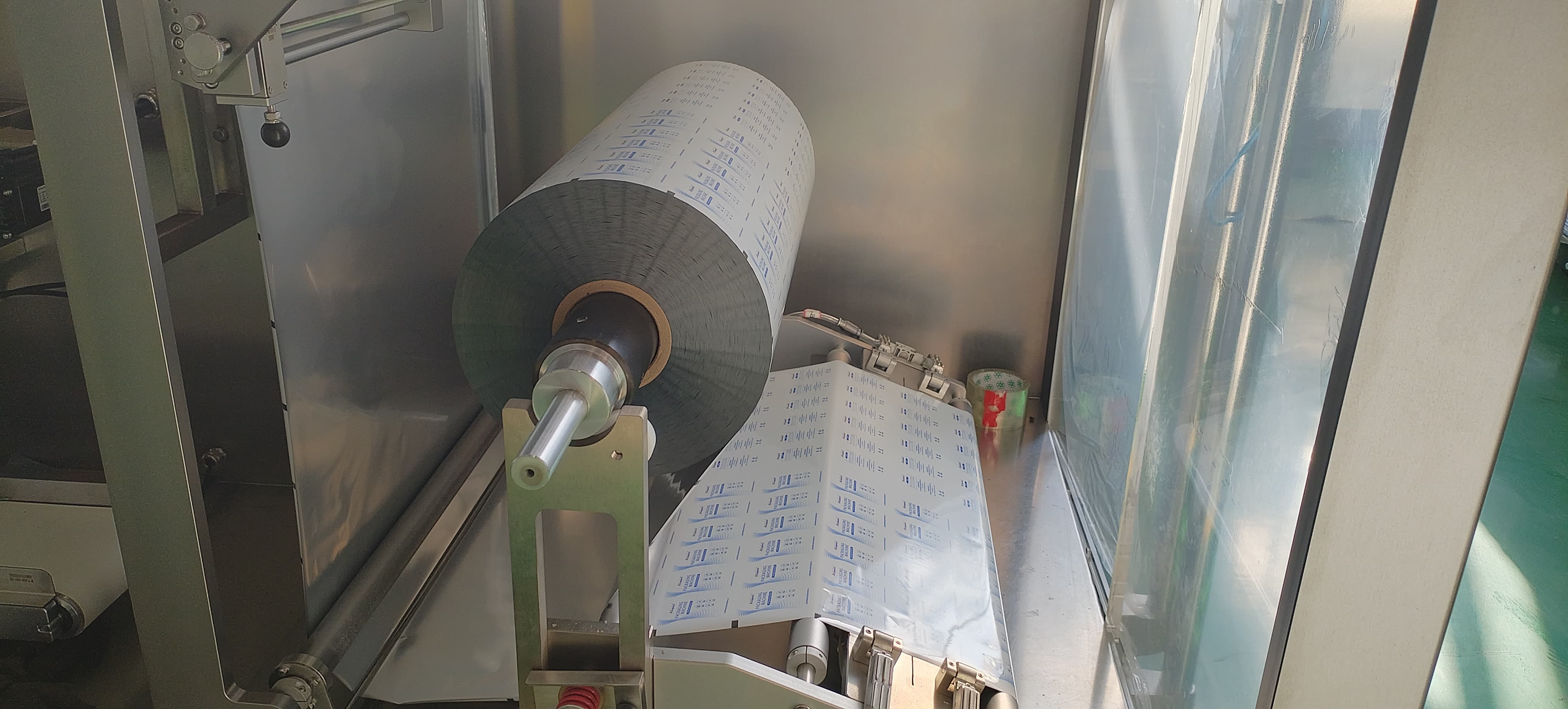

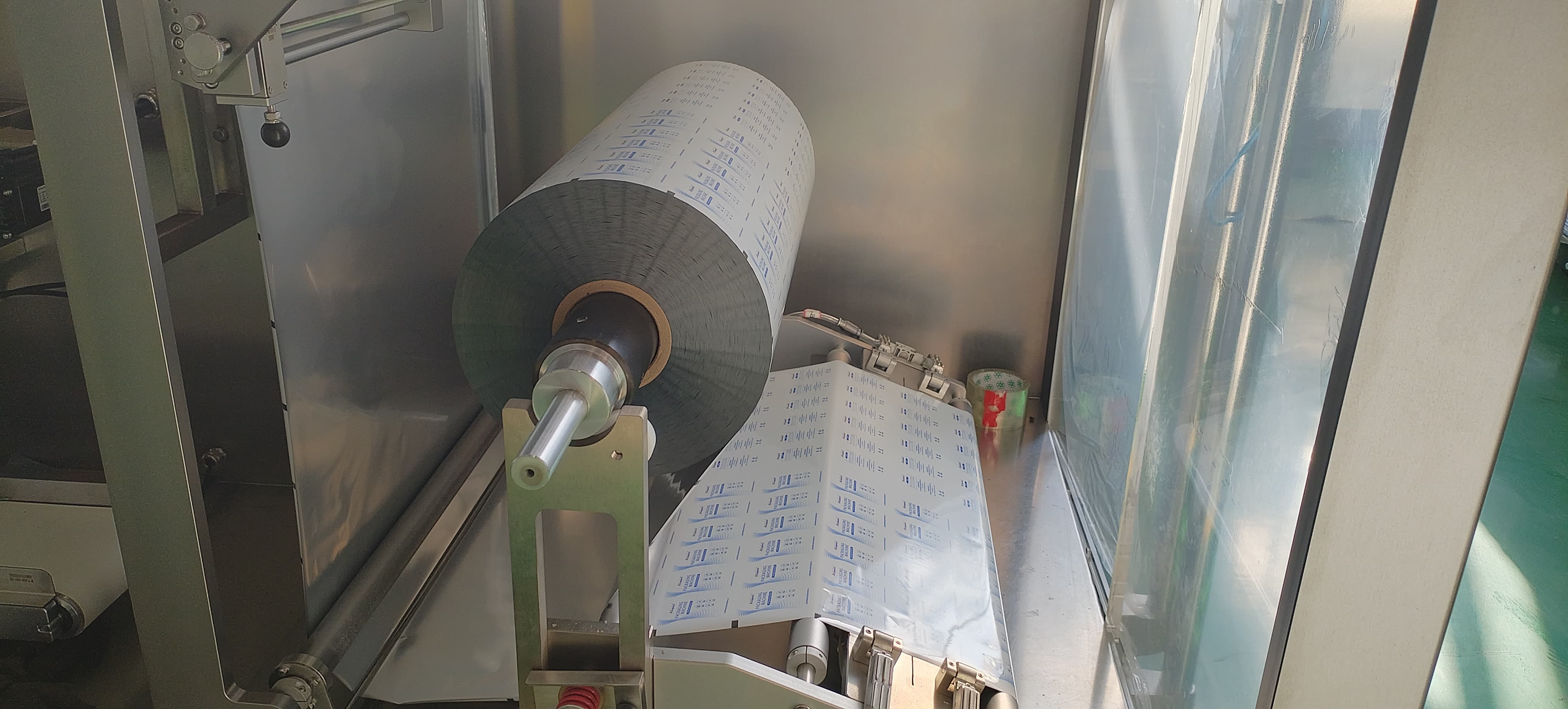

2. Pouch Formation:

- Film Unwinding: A roll of packaging film is unwound and fed into the machine. The film is usually made of materials that provide the necessary barrier properties for the product being packaged.

- Pouch Creation: The film is formed into pouches or bags. This is typically done by folding the film and sealing the edges to create individual compartments for each product.

3. Filling:

- Product Insertion: Once the pouches are formed, the products are inserted into the open pouches. This can be done using automated filling systems that ensure precise placement and quantity.

- Controlled Environment: In some cases, the filling process may occur in a controlled environment to maintain product integrity, especially for sensitive items like pharmaceuticals or food.

4. Sealing:

- 4 Side Sealing: After the products are filled, the machine seals the pouches on all four sides. This is typically achieved using heat sealing, where heated sealing bars press the film together to create a strong bond.

- Temperature and Pressure Control: The machine controls the temperature and pressure applied during sealing to ensure a secure and consistent seal.

5. Cutting:

- Separation of Pouches: Once sealed, the pouches are cut apart, creating individual packages. This can be done using a cutting mechanism that operates in sync with the sealing process.

6. Output and Collection:

- Conveyor System: The finished packages are then transported away from the machine using a conveyor system for further processing, labeling, or packing.

- Quality Control: Some machines are equipped with quality control systems that check for proper sealing, fill levels, and overall package integrity.

7. Automation and Control:

- User Interface: Operators can control and monitor the machine through a user-friendly interface, allowing for adjustments in speed, temperature, and other parameters.

- Data Logging: Many modern machines include data logging features to track production metrics and ensure compliance with quality standards.

Summary:

In summary, the multi-lane 4 side sealing packaging machine works by automating the entire packaging process, from product feeding and pouch formation to filling, sealing, and cutting. Its design allows for high efficiency and versatility, making it suitable for a wide range of products across various industries. The combination of automation, precision, and speed contributes to its effectiveness in modern packaging operations.