In the fast-paced world of pharmaceutical manufacturing, efficiency and precision are paramount. One of the most innovative solutions to emerge in recent years is the Multi-Lane Vertical Form-Fill-Seal (VFFS) Stick-Pack Machine for liquid pharmaceutical products. This advanced technology not only streamlines the packaging process but also ensures compliance with stringent industry standards. In this blog, we will explore the features and benefits of this cutting-edge machine through a Q&A format.

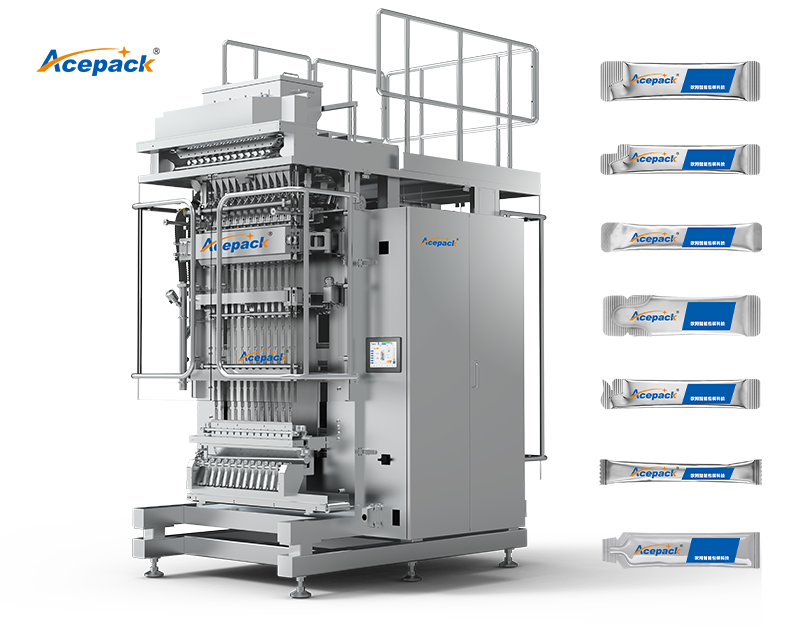

What is a Multi-Lane Vertical Form-Fill-Seal Stick-Pack Machine?

A Multi-Lane Vertical Form-Fill-Seal Stick-Pack Machine is a specialized piece of equipment designed for the packaging of liquid pharmaceutical products into stick packs. This machine operates by forming, filling, and sealing the packaging in a continuous process, allowing for high-speed production. The multi-lane design enables multiple stick packs to be produced simultaneously, significantly increasing output.

How does this machine enhance operational efficiency?

The machine is equipped with a full servo control system that enhances Overall Equipment Effectiveness (OEE). This means that it can operate at optimal speeds while minimizing downtime and waste. With the ability to achieve speeds of 70-80 cuts per minute, the Multi-Lane VFFS Stick-Pack Machine ensures that production lines can keep up with high demand without sacrificing quality.

What customization options are available for metering methods?

One of the standout features of this machine is its ability to achieve various customized metering methods. This flexibility allows manufacturers to tailor the filling process to meet the specific requirements of different liquid products. Whether it’s a viscous solution or a more fluid formulation, the machine can be adjusted to ensure accurate and consistent filling.

How does the machine ensure compliance with industry regulations?

Compliance with Environmental, Health, and Safety (EHS) management requirements is critical in the pharmaceutical industry. The Multi-Lane VFFS Stick-Pack Machine is designed with these regulations in mind. It incorporates features such as audit trails and electronic signatures, which are essential for maintaining traceability and accountability in the manufacturing process. Additionally, the machine’s design minimizes the risk of contamination, further ensuring compliance with safety standards.

What role does the human-machine interface play in operation?

The machine features an 18.5-inch large industrial control screen and a newly designed human-machine interface (HMI). This user-friendly interface allows operators to easily monitor and control the packaging process. The intuitive design reduces the learning curve for new operators and enhances overall productivity. Operators can quickly access data statistics, adjust settings, and troubleshoot issues, all from a centralized control panel.

How does the automatic nitrogen filling function work?

To preserve the integrity of liquid pharmaceutical products, the machine includes an automatic nitrogen filling function. This feature helps to displace residual oxygen within the packaging, controlling it to within 2%. By minimizing oxygen exposure, the machine helps to extend the shelf life of sensitive products and maintain their efficacy. This is particularly important for pharmaceuticals that may degrade when exposed to air.

Can this machine provide end-to-end solutions for manufacturers?

Absolutely! The Multi-Lane VFFS Stick-Pack Machine is designed to provide customized end-to-end solutions for liquid pharmaceutical packaging. From initial product formulation to final packaging, this machine can be integrated into existing production lines or used as a standalone solution. Manufacturers can benefit from a seamless workflow that enhances productivity and reduces the risk of errors.

What are the advantages of stick-pack packaging for liquid pharmaceuticals?

Stick-pack packaging offers several advantages for liquid pharmaceuticals. Firstly, it provides a convenient and portable format that is easy for consumers to use. The single-serving size reduces the risk of contamination and ensures accurate dosing. Additionally, stick packs are lightweight and take up less space, making them cost-effective for shipping and storage. The packaging also allows for eye-catching designs that can enhance brand visibility on retail shelves.

How does the machine contribute to sustainability in packaging?

Sustainability is a growing concern in the pharmaceutical industry, and the Multi-Lane VFFS Stick-Pack Machine contributes to this effort in several ways. The precise filling capabilities reduce material waste, while the compact design of stick packs minimizes the use of packaging materials. Furthermore, the machine’s compliance with EHS management requirements ensures that it operates within environmentally friendly parameters.

What should manufacturers consider when investing in a stick-pack machine?

When considering an investment in a Multi-Lane VFFS Stick-Pack Machine, manufacturers should evaluate their specific production needs. Factors such as the types of products being packaged, production volume, and regulatory requirements should all be taken into account. Additionally, it’s essential to choose a machine that offers flexibility and customization options to adapt to changing market demands.

Conclusion

The Multi-Lane Vertical Form-Fill-Seal Stick-Pack Machine for liquid pharmaceutical products represents a significant advancement in packaging technology. With its ability to achieve customized metering methods, ensure compliance with industry regulations, and enhance operational efficiency, this machine is a game-changer for manufacturers. As the pharmaceutical industry continues to evolve, investing in such innovative solutions will be crucial for staying competitive and meeting the demands of consumers. Whether you are looking to streamline your production process or enhance product integrity, this machine offers a comprehensive solution that can transform your packaging operations.