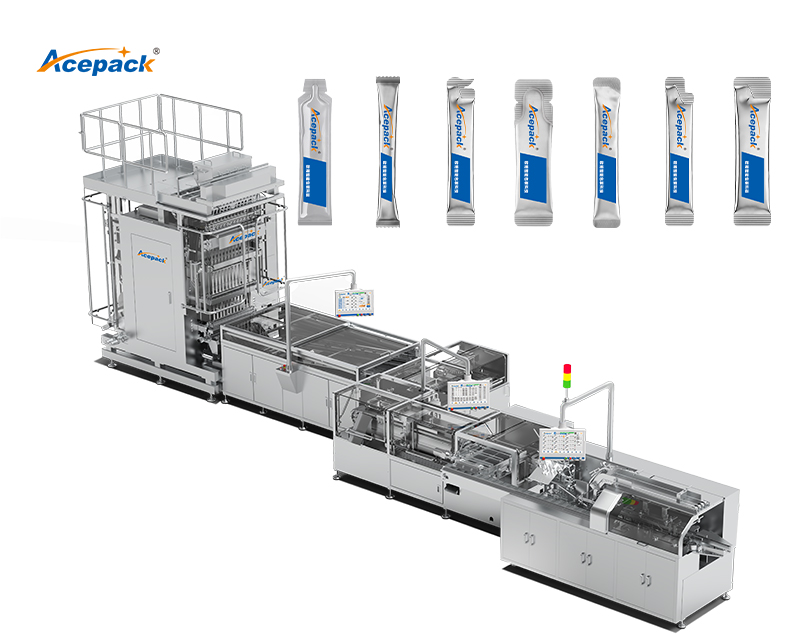

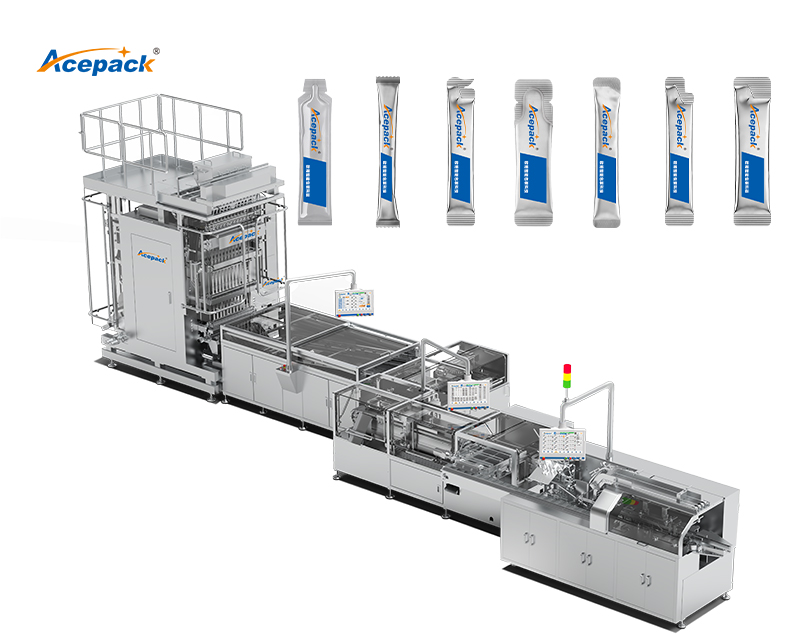

In the ever-evolving pharmaceutical industry, the demand for efficient, reliable, and customizable packaging solutions is paramount. One of the most innovative advancements in this field is the pharmaceutical stick pack packaging machine. These machines are designed to meet the unique needs of pharmaceutical products, offering a range of benefits that enhance productivity, compliance, and product integrity. In this article, we will explore the key benefits of using pharmaceutical stick pack packaging machines, highlighting their features and capabilities.

Enhanced Customization and Metering

One of the standout features of pharmaceutical stick pack packaging machines is their ability to achieve various customized metering methods. This flexibility allows manufacturers to tailor the packaging process to the specific requirements of different products. Whether it’s powders, granules, or liquids, these machines can accommodate a wide range of formulations, ensuring that each product is packaged accurately and efficiently. This level of customization not only improves the quality of the final product but also enhances customer satisfaction by providing tailored solutions.

Compliance with Regulatory Standards

In the pharmaceutical industry, compliance with regulatory standards is non-negotiable. Pharmaceutical stick pack packaging machines are designed to meet stringent requirements, including audit trails, electronic signatures, and data statistics. These features ensure that every step of the packaging process is documented and traceable, providing manufacturers with the necessary tools to comply with industry regulations. By integrating these compliance functions into the packaging process, companies can minimize the risk of errors and enhance their overall operational efficiency.

User-Friendly Interface

The user experience is a critical factor in the efficiency of any packaging operation. Pharmaceutical stick pack packaging machines come equipped with an 18.5-inch large industrial control screen and a newly designed human-machine interface. This intuitive interface simplifies the operation of the machine, allowing operators to easily navigate through various settings and functions. The user-friendly design reduces the learning curve for new operators and minimizes the likelihood of operational errors, ultimately leading to increased productivity.

Full Servo Control System

The implementation of a full servo control system in pharmaceutical stick pack packaging machines significantly enhances Overall Equipment Effectiveness (OEE). This advanced technology allows for precise control over the packaging process, resulting in improved speed, accuracy, and consistency. With stable speeds reaching 70-80 cuts per minute, manufacturers can achieve higher output rates without compromising on quality. The servo control system also reduces wear and tear on the machine, leading to lower maintenance costs and extended equipment lifespan.

Environmental Health and Safety Compliance

In today’s environmentally conscious world, compliance with Environmental Health and Safety (EHS) management requirements is essential for pharmaceutical manufacturers. Pharmaceutical stick pack packaging machines are designed with EHS compliance in mind, ensuring that the packaging process adheres to environmental regulations and safety standards. This commitment to sustainability not only protects the environment but also enhances the company’s reputation and fosters trust among consumers.

Nitrogen Filling Function

One of the critical aspects of pharmaceutical packaging is ensuring product integrity and stability. Pharmaceutical stick pack packaging machines are equipped with an automatic nitrogen filling function, which controls residual oxygen levels within 2%. This feature is particularly important for sensitive products that may be affected by exposure to oxygen, such as certain pharmaceuticals and nutraceuticals. By minimizing oxygen exposure, manufacturers can extend the shelf life of their products and maintain their efficacy, ultimately benefiting both the company and the end consumer.

Customized End-to-End Solutions

Every pharmaceutical manufacturer has unique needs and challenges. Pharmaceutical stick pack packaging machines provide customized end-to-end solutions that cater to these specific requirements. From initial product formulation to final packaging, these machines can be integrated into a comprehensive packaging line that streamlines the entire process. This holistic approach not only improves efficiency but also reduces the risk of errors and enhances overall product quality.

Conclusion

In conclusion, pharmaceutical stick pack packaging machines offer a multitude of benefits that are essential for modern pharmaceutical manufacturing. From enhanced customization and compliance with regulatory standards to user-friendly interfaces and advanced technology, these machines are designed to meet the unique challenges of the industry. By investing in pharmaceutical stick pack packaging machines, manufacturers can improve their operational efficiency, ensure product integrity, and ultimately deliver high-quality products to consumers. As the pharmaceutical industry continues to evolve, the adoption of innovative packaging solutions will be crucial for staying competitive and meeting the demands of the market.