https://www.acepackgroup.com/product_detail/46.htmlExpert's Note: I’m Lee, and after 20 years at Acepack, I’ve helped hundreds of factory managers solve the "bottleneck" problem. If your production line is struggling with leakage, slow speeds, or high waste, you don't just need a machine—you need a precision-engineered solution.

What is an Acepack Packing Machine?

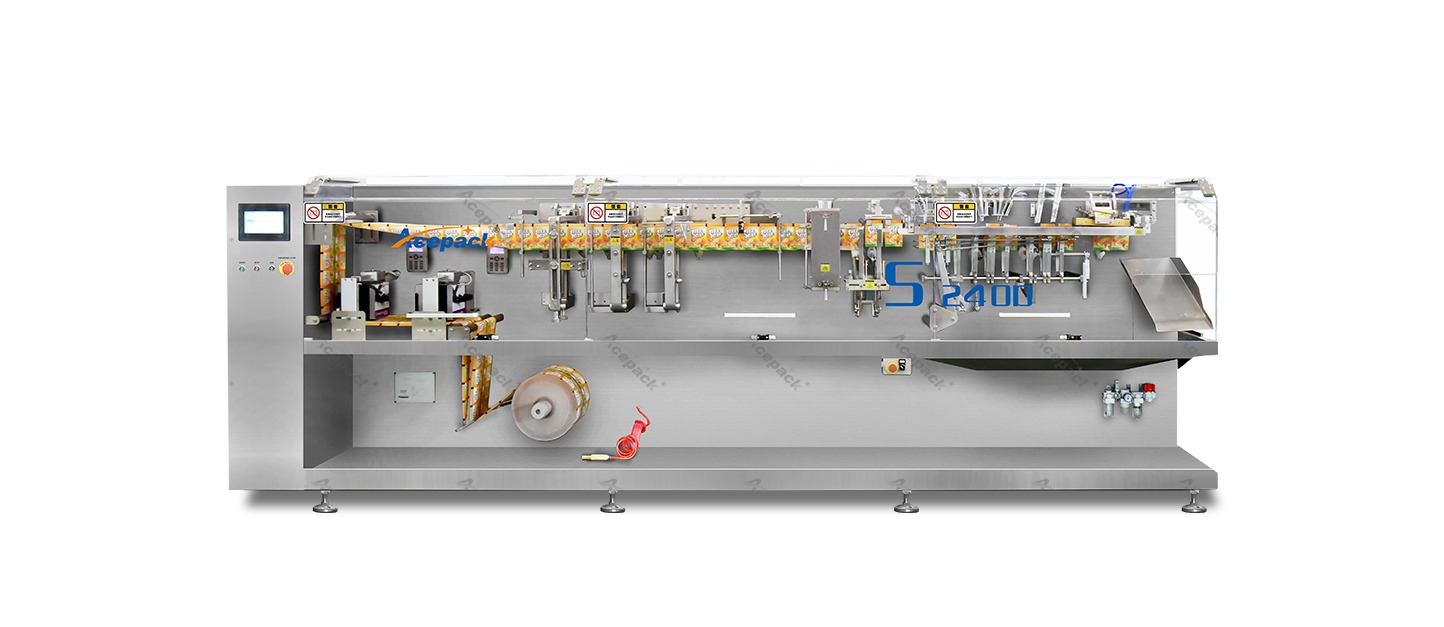

An Acepack packing machine is a high-performance Horizontal Form Fill Seal (HFFS) system. Engineered in our Shanghai R&D center, these machines are designed to transform roll film or premade bags into retail-ready packaging for liquids, powders, and granules.

Technology: Fully automatic horizontal flow.

Efficiency: Designed to minimize film waste and maximize airtight seal integrity.

Reliability: Built with global standard components for 24/7 industrial operation.

Choosing the Right Acepack Series for Your Product

Are you overwhelmed by choices? Based on my 20 years of experience, here is the breakdown of our core technology series:

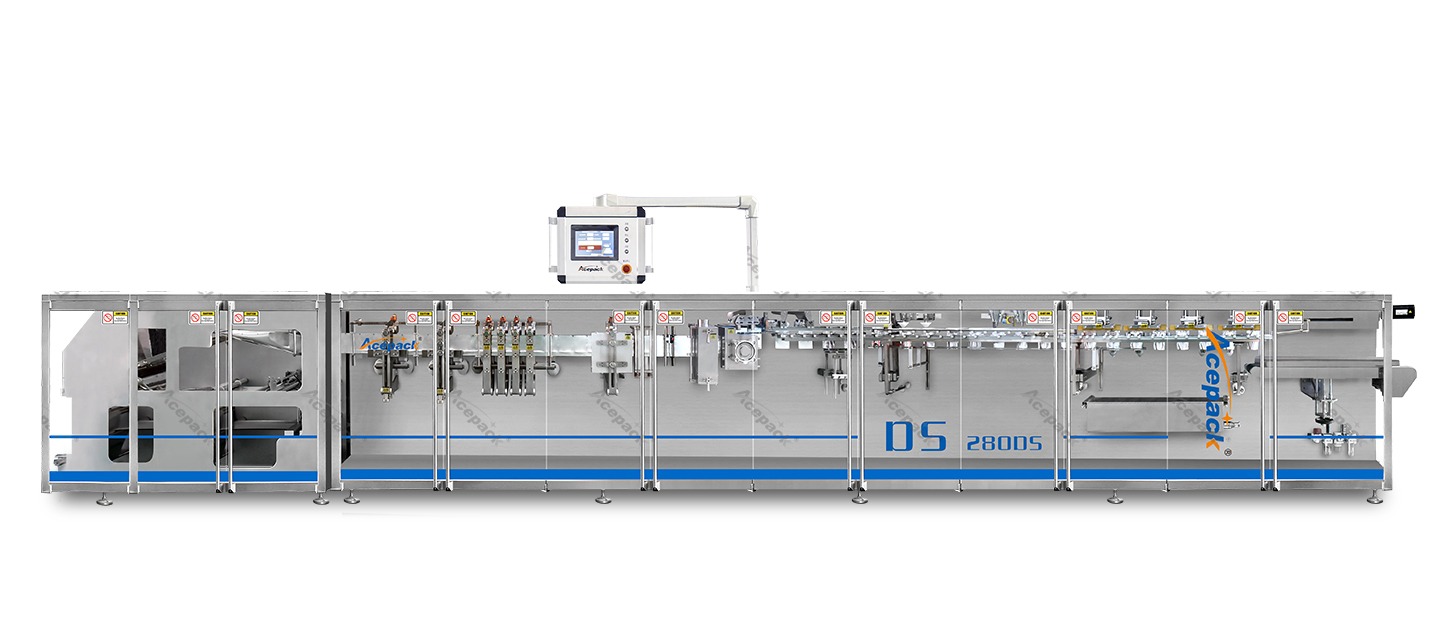

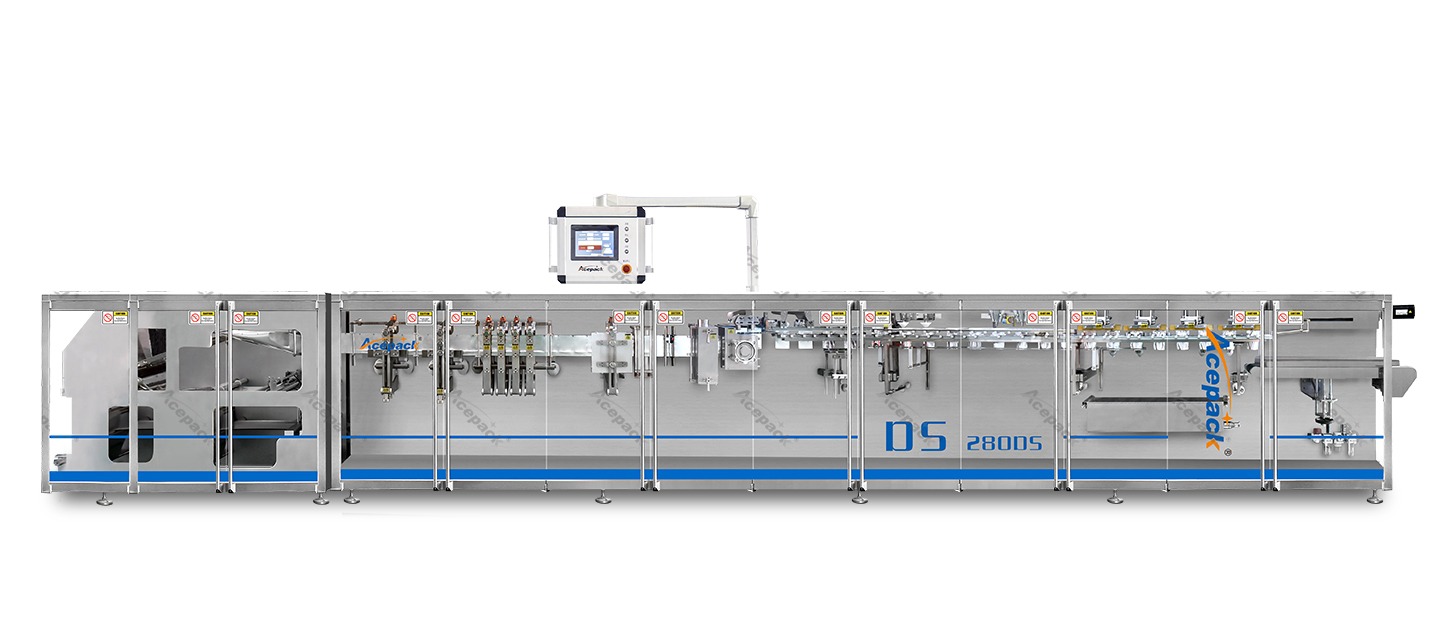

The DS Series is our flagship line for manufacturers looking to produce high-quality Stand-up Pouches (Doypack) directly from roll film.

Cost-Efficiency: Saves up to 30% on material costs compared to pre-made bags.

Versatility: The DS-180S is the industry workhorse, while the DS-180SZ integrates automatic zipper application for resealable snacks or pet food.

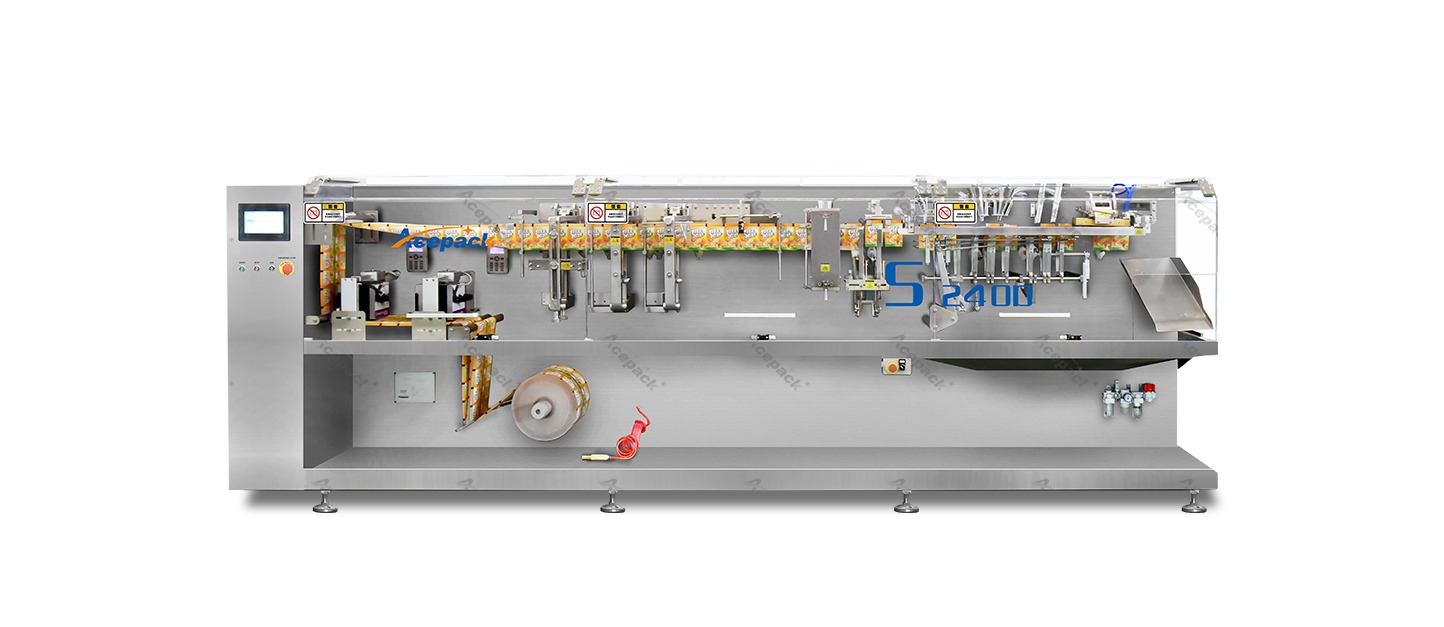

Ideal for flat sachets (ketchup, shampoo samples).

When volume is your priority, the HS Series delivers.

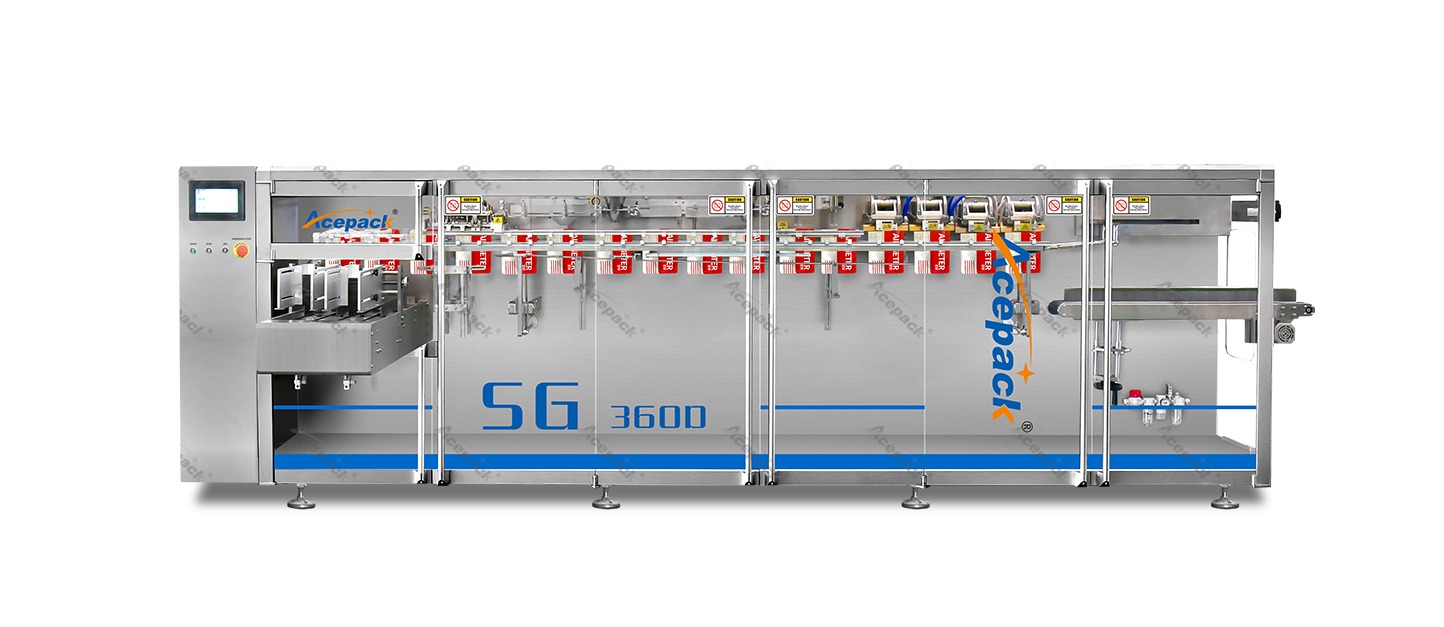

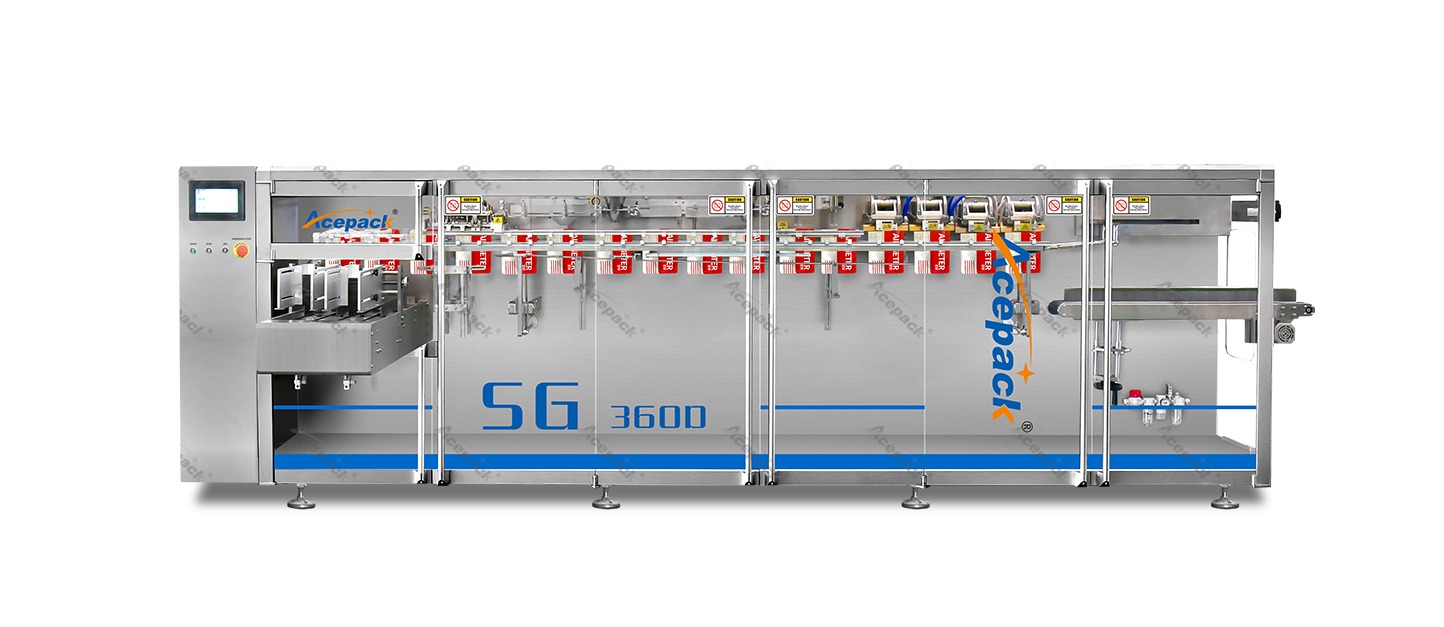

For brands using complex, custom-shaped bags, the SG Series handles the picking, opening, and sealing of pre-manufactured pouches with surgical precision.

Quick Comparison Table

| Series | Machine Type | Best For | Max Speed (approx.) |

| DS Series | Stand-up Pouch | Juice, Detergents, Snacks | 40-80 ppm |

| S Series | Flat Sachet | Condiments, Samples | 80-100 ppm |

| HS Series | High Speed | Pharma, Sugar, Chemicals | 160-320 ppm |

| SG Series | Premade Bag | Irregular Shapes, Luxury Packaging | 40-60 ppm |

Technical Excellence: How It Works

Horizontal machines provide a superior seal compared to vertical machines because they allow for longer dwell times and better seal cooling.

The 3-Step Precision Process:

Forming: A forming plow folds the film, while ultrasonic or thermal tools create the gusset and side seals.

Filling: We customize the filler based on your product's viscosity or density:

Liquids: Servo-driven Magnetic or Hibar Pumps (±1% accuracy).

Powders: Servo Auger Fillers (Dust-free operation).

Granules: Multi-head weighers for high-speed precision.

Sealing & Verification: Dual-stage top sealing ensures zero leakage. Every bag passes through a Check Weigher and Metal Detector before robotic palletizing.

Global Trust & Industry Applications

We don't just build machines; we comply with the world's strictest hygiene and safety standards.

Food & Beverage: Using SS304/SS316 stainless steel. Trusted by New Hope and Nanshan.

Pharmaceuticals: High-pressure sealing jaws ensure airtight integrity for giants like Bayer and Sinopharm.

Daily Chemicals: Anti-foaming diving nozzles for P&G, Unilever, and Liby.

Agro-Chemicals: Corrosion-resistant components for fertilizers and pesticides.

Why Acepack is the Global Leader in HFFS

20+ Years of Mastery: Headquartered in Shanghai with a focus on "Artisan Innovation."

IP & Patents: Over 80 patents and 10 software copyrights. We lead where others follow.

Certifications: Fully CE, UL, and ISO9001 certified, ensuring compliance in any global market.

Turnkey Solutions: We provide the entire line—from the initial bagger to the final robotic case packer.

Conclusion

Acepack delivers the intersection of speed, intelligence, and reliability. Whether you are a startup or a global enterprise, we have the engineering expertise to scale your production.

Ready to upgrade your production line?

[Contact Lee today for a customized technical consultation]