In the competitive world of powdered products—from nutritional supplements and dairy powders to spices and chemicals—packaging is not just a final step; it's a critical component of brand identity, product protection, and operational efficiency. Enter the automatic horizontal filling and sealing machine for powder. This engineering marvel has revolutionized how businesses package dry, flowable products. But what exactly is this machine, and how can it transform your production line?

This comprehensive guide delves into the intricacies of this technology, providing you with the knowledge needed to make an informed decision.

How Does an Automatic Horizontal Facing and Sealing Machine Actually Work?

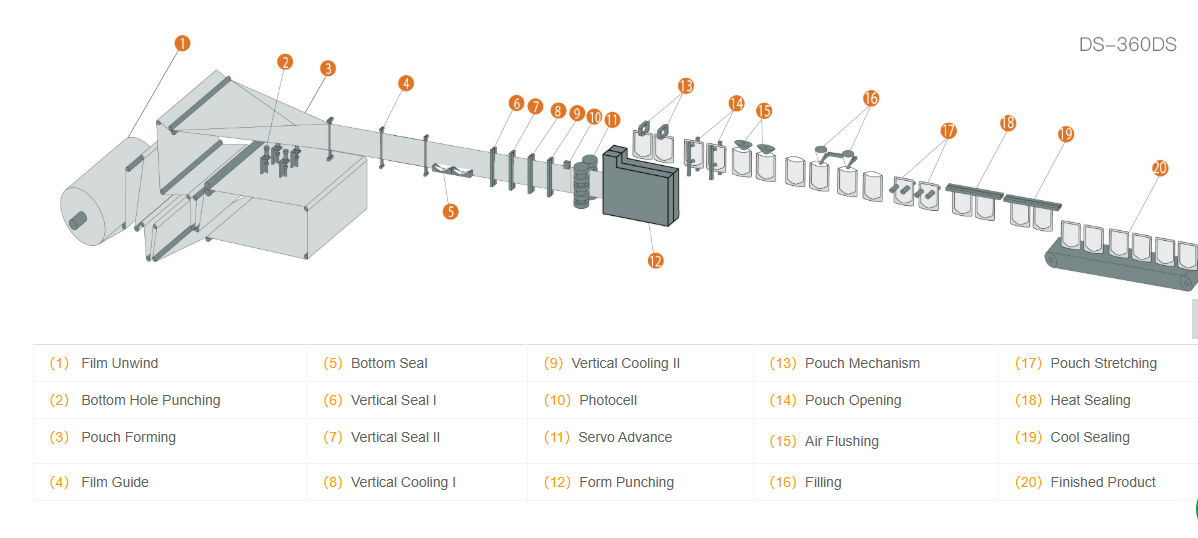

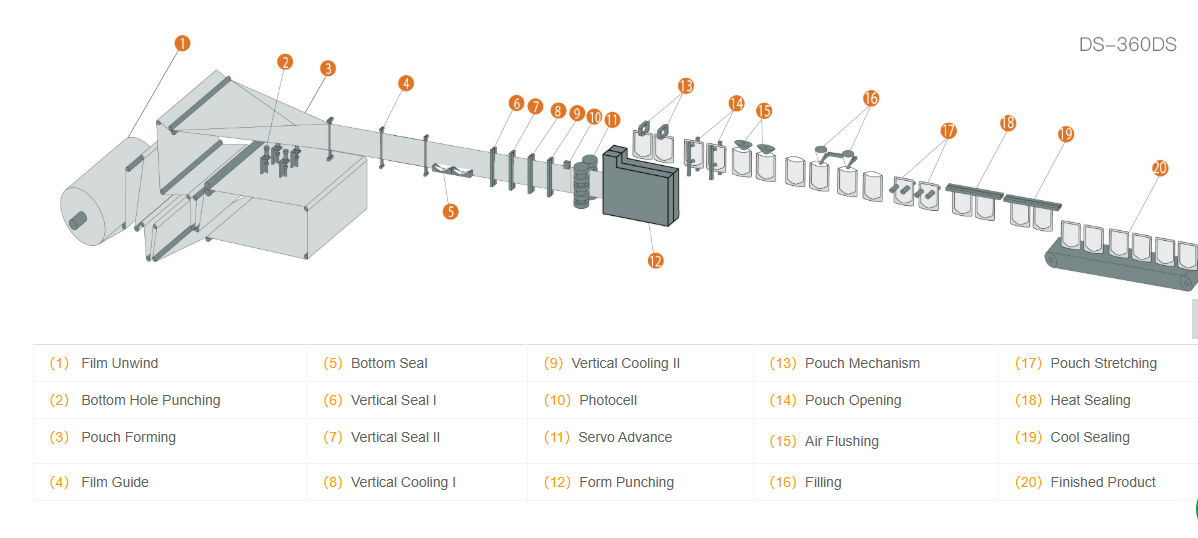

Understanding the core mechanism is key to appreciating its value. Unlike vertical machines that work with pre-made bags, a horizontal machine creates the package from a roll of film, offering unparalleled flexibility. The process is a continuous, synchronized ballet of mechanical precision:

Film Unwinding & Forming: A roll of packaging film (laminate or composite) is mounted on the machine. The film is fed through a series of tensioners and guides into a forming shoulder. This shoulder expertly shapes the flat film into a continuous tube.

Longitudinal Sealing: As the film is shaped into a tube, the two edges are brought together and sealed along the length by a heated sealing bar, creating a robust back seal.

Product Filling: The powder is transported from a hopper above the machine into a volumetric or auger filler. At the precise moment, the filler dispenses a pre-measured amount of powder down through a filling tube and into the newly formed film tube.

Transverse Sealing & Cutting: The now-filled tube is pulled downward. A pair of heated sealing jaws close simultaneously, creating the top seal of the current pouch and the bottom seal of the next pouch. A cutting mechanism, often integrated into the jaws, then separates the finished pouch from the continuous tube.

This cycle repeats at high speeds, producing dozens, even hundreds, of perfectly sealed pouches per minute.

What Are the Unbeatable Advantages of Automating Your Powder Packaging?

Switching from manual or semi-automatic processes to a fully automatic horizontal filling and sealing machine for powder delivers a cascade of benefits:

Dramatically Increased Speed and Output: Achieve production speeds of 60 to 200+ pouches per minute, depending on the model and pouch size, meeting high-volume demands with ease.

Exceptional Dosing Accuracy: Advanced auger fillers with servo motors ensure each pouch receives the exact same weight of product, minimizing give-away and ensuring compliance with regulatory net weight requirements.

Enhanced Product Integrity and Shelf Life: The hermetic seals created by the machine protect the powder from moisture, oxygen, and contaminants, significantly extending shelf life and maintaining product quality.

Substantial Labor and Cost Savings: Automation reduces dependency on manual labor for filling and sealing, cutting long-term operational costs and minimizing human error.

Unmatched Packaging Versatility: With a simple change of the forming shoulder and sealing jaws, you can switch between different pouch sizes and styles (e.g., pillow bags, gusseted bags) quickly, making short production runs economical.

Which Type of Filling System is Best for Your Powder?

Not all powders are created equal. Their flowability, density, and aeriation properties dictate the ideal filling system. The two most common types in a horizontal form fill seal machine are:

Auger Filling System: The industry standard for powders. A rotating screw (auger) inside a tube dispenses the product based on a specific number of revolutions. It's highly accurate for most free-flowing and non-free-flowing powders. For cohesive powders, agitators or vibration systems can be added to the hopper to prevent bridging.

Volumetric Cup Filling System: This system uses measuring cups to dispense product. It is excellent for consistent-density, free-flowing powders and is often a more economical option. However, it may be less accurate if the powder's density varies.

What Critical Factors Should You Consider Before Purchasing a Machine?

Investing in an automatic powder packaging machine is significant. Asking the right questions is crucial:

What are my primary and secondary powder characteristics? (e.g., density, flowability, particle size, hygroscopic nature)

What is my required production speed (pouches per minute)?

What is my target pouch size range? (Length, Width, and the gram weight fill)

What film material will I be using? (e.g., PET/AL/PE, PET/MPET/PE, OPP/CPP)

What level of dosing accuracy is legally and commercially required?

Do I need additional features? (e.g., gas flushing for nitrogen flushing, date coding, check-weighing, zipper application)

Conclusion: Is an Automatic Horizontal Filling and Sealing Machine the Right Investment for You?

If your business deals with packaging powders in pouches and faces challenges with speed, accuracy, or rising labor costs, the answer is a resounding yes. An automatic horizontal filling and sealing machine for powder is more than just a piece of equipment; it's a strategic asset. It future-proofs your operation, enhances your brand consistency, and delivers a strong return on investment through efficiency and waste reduction. By carefully assessing your product needs and production goals, you can select the perfect machine to drive your growth for years to come.