In the realm of automated packaging, precision and efficiency are paramount. For premade pouch packing machines, a key component contributing to these qualities is the "Servo WB structure." The "WB" in this terminology stands for "Walking Beam," a mechanism responsible for the precise and intermittent movement of pouches through the various stages of the packaging process. The "Servo" designation indicates that this walking beam is driven by advanced servo motors, offering a high degree of control over motion.

The Mechanics of a Walking Beam System

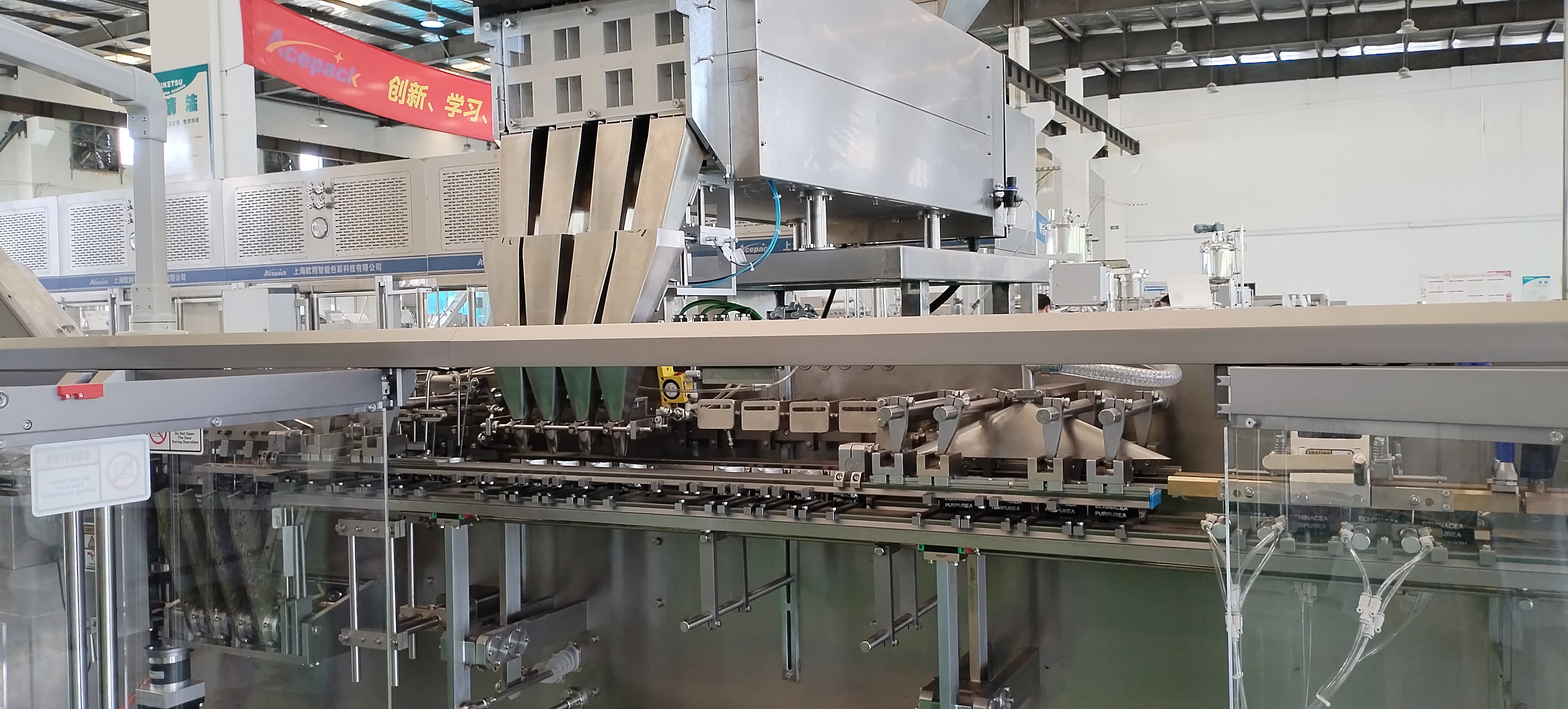

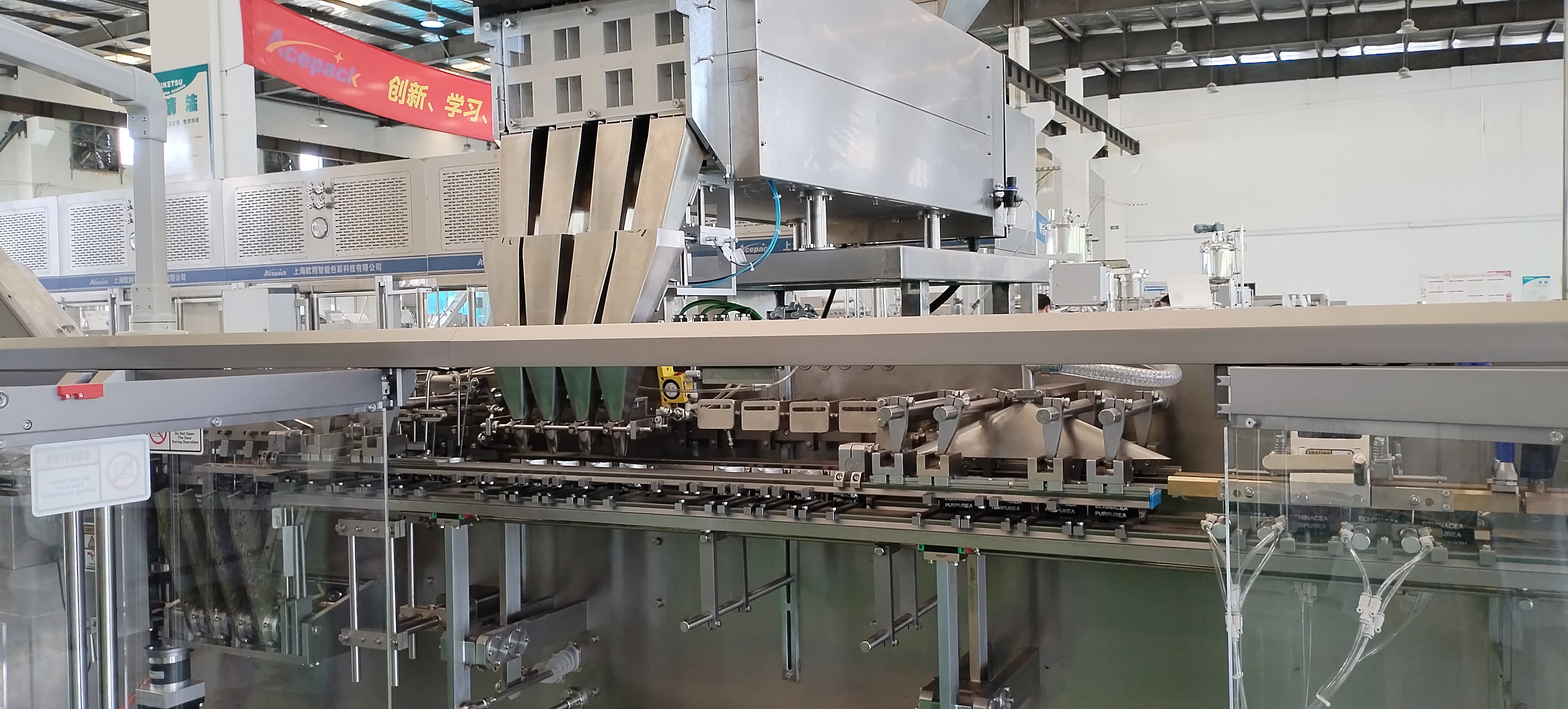

A walking beam is a conveyance system that moves items in a series of precise steps. It typically consists of one or more moving beams and a stationary beam. The moving beam lifts the pouches, carries them forward a set distance, lowers them back onto the stationary beam, and then returns to its original position to start the next cycle. This step-by-step motion ensures that the pouches are accurately positioned at each station of the packaging machine.

The typical workflow of a premade pouch packing machine utilizing a Servo WB structure involves the following stations:

Pouch Feeding and Gripping: Premade pouches are individually picked from a magazine and securely gripped.

Pouch Opening: The walking beam transports the pouch to a station where it is opened.

Filling: The open pouch is then moved to the filling station where the product is dispensed.

Sealing: Finally, the filled pouch is transferred to the sealing station to be hermetically sealed.

Discharge: The sealed pouch is then released from the machine.

The Servo WB structure is responsible for the accurate and synchronized movement of the pouches between each of these critical stages.

The Advantages of a Servo-Driven System

The integration of servo motors to drive the walking beam mechanism provides significant advantages over traditional mechanical or pneumatic systems.Servo motors allow for precise control over the position, speed, and torque of the moving components.This level of control translates into several key benefits for premade pouch packing machines:

Enhanced Precision and Accuracy: Servo motors ensure highly accurate and repeatable positioning of the pouches at each station.This is crucial for consistent filling and high-quality sealing.

Increased Speed and Efficiency: Servo-driven systems can operate at high speeds with smooth acceleration and deceleration, leading to a higher throughput of packaged products.

Flexibility and Quick Changeovers: The parameters of the servo motors can be easily adjusted through a control interface. This allows for quick and seamless changeovers to accommodate different pouch sizes and product types, reducing downtime.

Gentle Handling: The smooth and controlled movements of the servo-driven walking beam minimize the risk of damage to the pouches or the product, which is especially important for delicate items.

Reduced Maintenance: Servo-driven systems have fewer mechanical parts compared to complex mechanical linkages, leading to less wear and tear and reduced maintenance requirements.

Improved Rigidity and Load Bearing: As noted in manufacturer specifications, Servo WB structures are designed for good rigidity and can handle a significant load, ensuring stable operation even with heavier products.

In conclusion, the Servo WB structure is a sophisticated and highly efficient conveyance system within premade pouch packing machines. By combining the precise, step-by-step motion of a walking beam with the advanced control of servo motors, this structure ensures accurate positioning, high-speed operation, and the flexibility required in modern packaging environments.