In the ever-evolving world of health and wellness, probiotics have emerged as a powerhouse in promoting gut health and overall well-being. As the demand for these beneficial microorganisms continues to rise, so does the need for efficient and innovative packaging solutions. Enter the realm of probiotics stick pack packaging machines—an essential tool for manufacturers looking to streamline their production processes while ensuring product integrity and quality.

The Importance of Packaging in the Probiotics Industry

Packaging plays a crucial role in the probiotics industry. It not only protects the product from external factors but also preserves its potency and effectiveness. Probiotics are sensitive to environmental conditions, and improper packaging can lead to a decrease in their viability. This is where advanced stick pack packaging machines come into play, offering a range of features designed to meet the unique needs of probiotic manufacturers.

Customized Metering Methods for Precision

One of the standout features of modern probiotics stick pack packaging machines is their ability to achieve various customized metering methods. This flexibility allows manufacturers to accurately dispense the right amount of probiotics into each stick pack, ensuring consistency and quality across the board. Whether it’s a single-serving or a bulk package, these machines can be tailored to meet specific production requirements, enhancing efficiency and reducing waste.

Advanced Functionality: Audit Trails and Electronic Signatures

In an industry where compliance and traceability are paramount, the integration of audit trails and electronic signatures in packaging machines is a game-changer. These features not only enhance accountability but also streamline the documentation process, making it easier for manufacturers to adhere to regulatory standards. With the ability to track every step of the packaging process, companies can ensure that their products meet the highest quality standards while maintaining transparency throughout the supply chain.

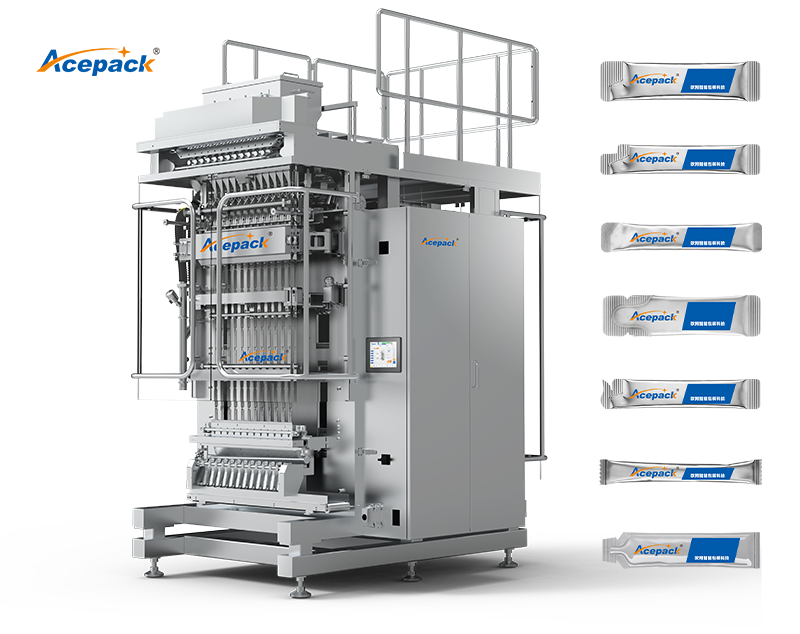

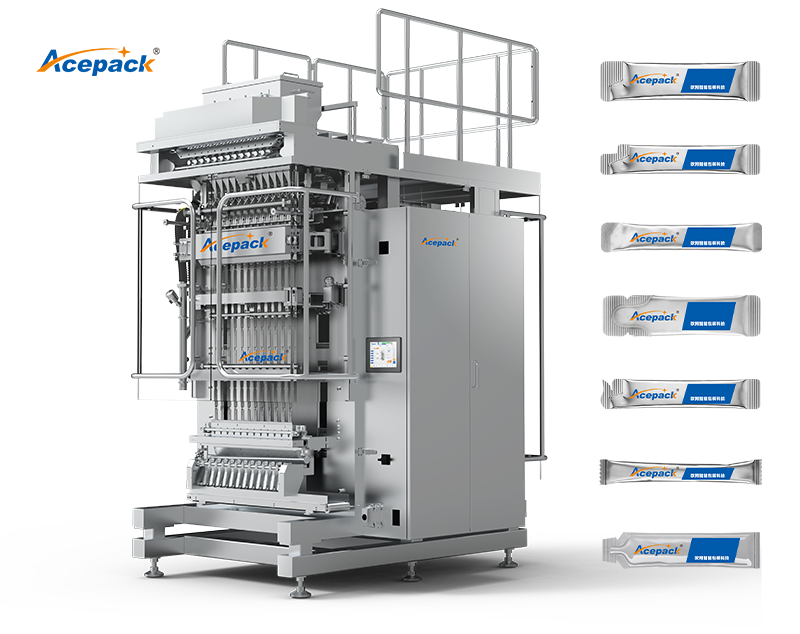

User-Friendly Interface and Control

Equipped with an 18.5-inch large industrial control screen, modern probiotics stick pack packaging machines boast a newly designed human-machine interface that prioritizes user experience. This intuitive interface allows operators to easily monitor and control the packaging process, reducing the likelihood of errors and improving overall productivity. The full servo control system further enhances Overall Equipment Effectiveness (OEE), ensuring that machines operate at optimal performance levels.

Speed and Efficiency: Cutting-Edge Technology

In today’s fast-paced market, speed is of the essence. Probiotics stick pack packaging machines are designed to meet this demand, with stable speeds reaching 70-80 cuts per minute. This impressive output not only increases production capacity but also allows manufacturers to respond quickly to market trends and consumer demands. By investing in high-speed packaging technology, companies can stay ahead of the competition while maintaining product quality.

Preserving Product Integrity with Nitrogen Filling

One of the most critical aspects of packaging probiotics is ensuring that the product remains viable throughout its shelf life. The automatic nitrogen filling function in modern stick pack machines plays a vital role in this process. By controlling residual oxygen levels within 2%, manufacturers can significantly extend the shelf life of their probiotics, preserving their potency and effectiveness. This feature is particularly important in an industry where product quality directly impacts consumer health.

End-to-End Solutions for Probiotic Manufacturers

The evolution of probiotics stick pack packaging machines has led to the development of customized end-to-end solutions for manufacturers. From initial product formulation to final packaging, these machines can be integrated into a comprehensive production line that streamlines operations and enhances efficiency. By providing tailored solutions that address the unique challenges of the probiotics industry, manufacturers can optimize their processes and deliver high-quality products to consumers.

Compliance with EHS Management Requirements

In an era where environmental, health, and safety (EHS) management is more important than ever, probiotics stick pack packaging machines are designed to comply with stringent EHS requirements. This commitment to safety and sustainability not only protects workers and consumers but also enhances the brand reputation of manufacturers. By prioritizing EHS compliance, companies can demonstrate their dedication to responsible production practices.

Conclusion: The Future of Probiotics Packaging

As the probiotics market continues to grow, the demand for innovative packaging solutions will only increase. Probiotics stick pack packaging machines represent the future of this industry, offering advanced features that enhance efficiency, product integrity, and compliance. By investing in these cutting-edge machines, manufacturers can not only meet the needs of today’s consumers but also position themselves for success in the ever-competitive health and wellness market.

In summary, the integration of customized metering methods, advanced functionality, user-friendly interfaces, high-speed capabilities, nitrogen filling technology, and EHS compliance makes probiotics stick pack packaging machines an indispensable asset for manufacturers. As we look ahead, it’s clear that these machines will play a pivotal role in shaping the future of probiotics packaging, ensuring that consumers receive the highest quality products while manufacturers operate at peak efficiency.