The rise of stand-up pouches (SUPs) as a preferred packaging format across food, beverage, pet care, cosmetics, and household products is undeniable. Their lightweight nature, shelf appeal, and sustainability advantages drive demand. However, efficiently and reliably filling these versatile pouches requires specialized equipment: the stand-up pouch filling machine. This guide delves into the technical workings, different types, and critical features of these essential packaging machines.

Understanding the Core Function:

At its heart, a stand-up pouch filling machine automates the process of accurately measuring a product and depositing it into a stand-up pouch, followed by a secure seal. This process replaces slow, inconsistent, and potentially unhygienic manual filling, significantly boosting production rates and quality control.

Primary Types of Stand-Up Pouch Filling Machines:

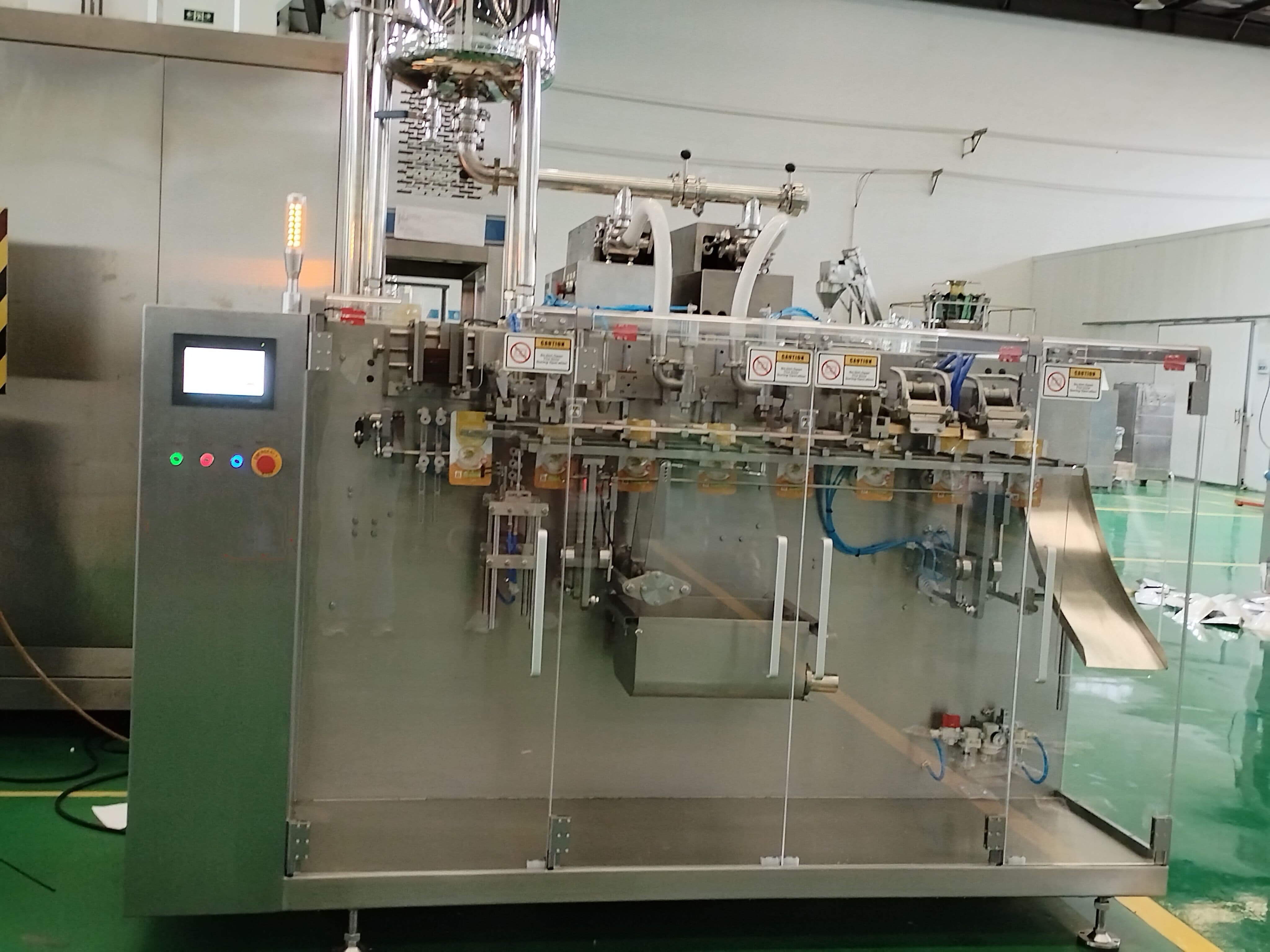

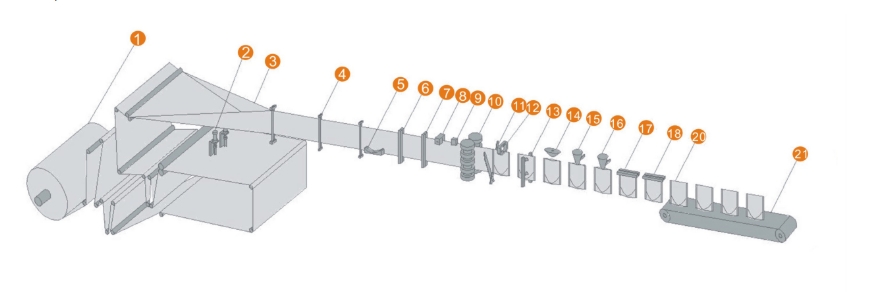

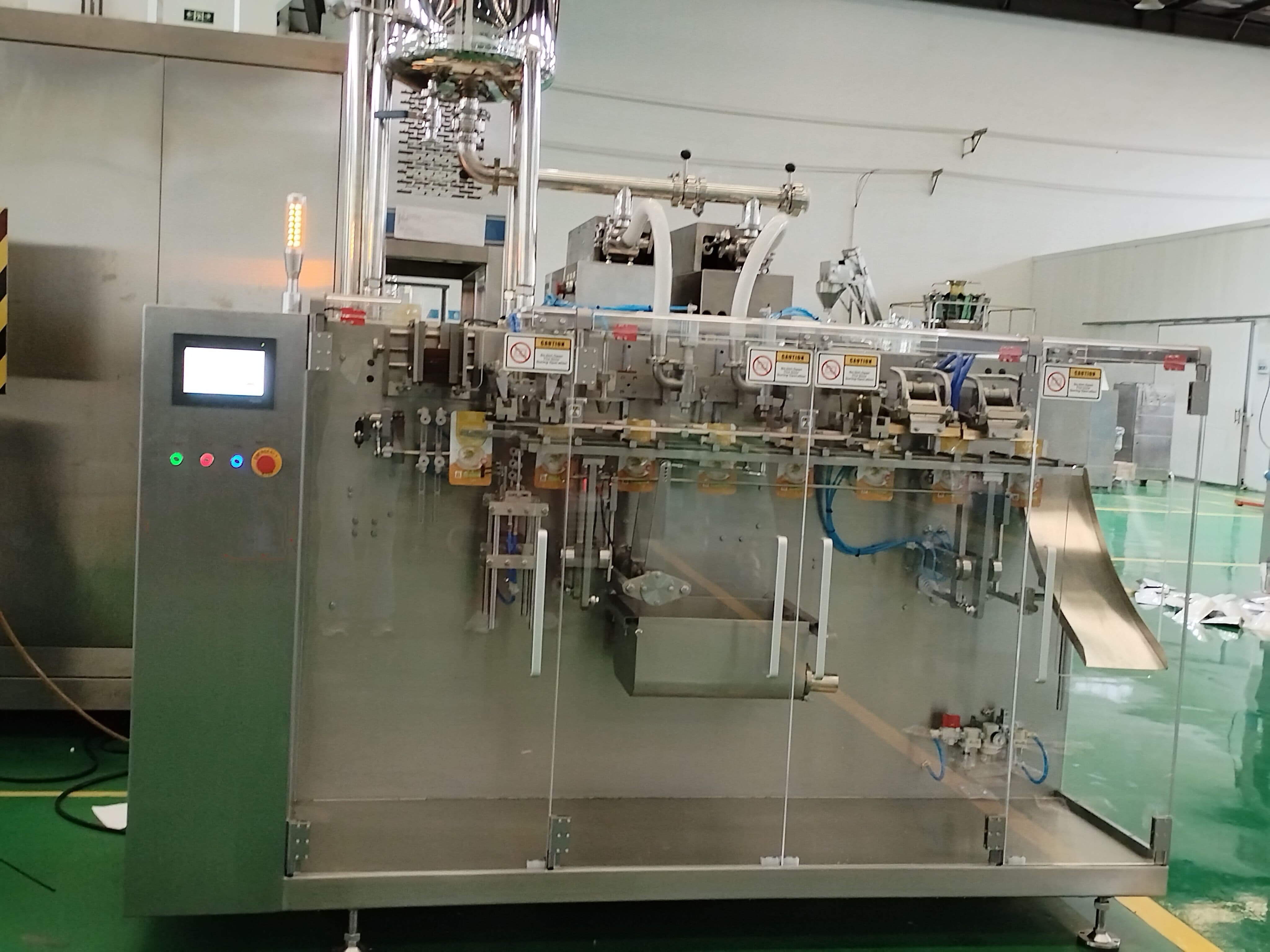

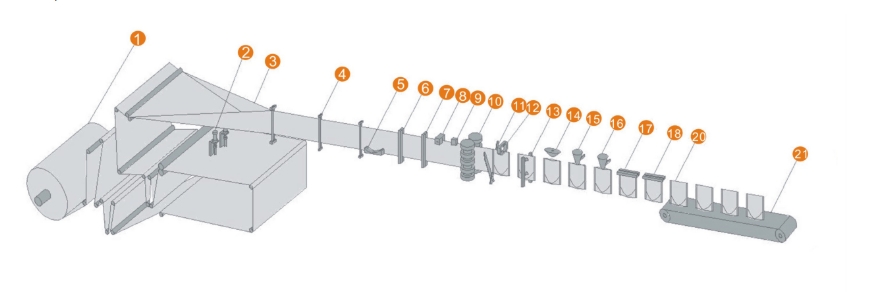

Horizontal Form-Fill-Seal (HFFS) Machines: These are the most common and versatile type for high-volume production.

How They Work: A continuous roll of flat packaging film (laminate) is fed Horizontally. The film is formed into a tube around a filling tube (collator). Horizontal seals create the bottom of one pouch and the top of the previous pouch simultaneously. The product is then dispensed through the filling tube into the newly formed pouch. Finally, the top of the filled pouch is sealed, and the pouch is cut free. Spouts or zippers can be integrated during the forming process if required.

Best For: High-speed production of spoutless pouches or pouches with integrated spouts/zips formed inline. Ideal for powders, granules, liquids, and some solids.

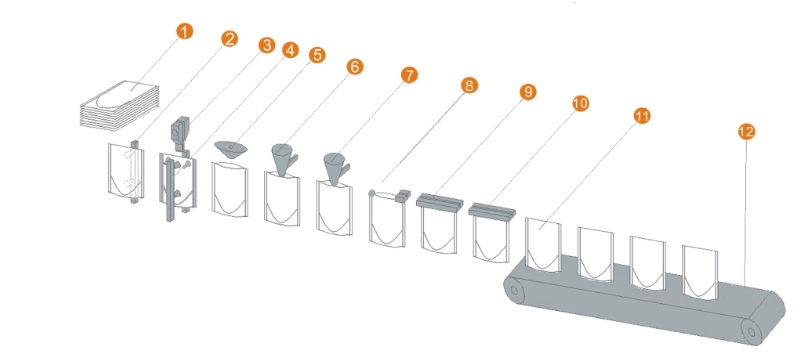

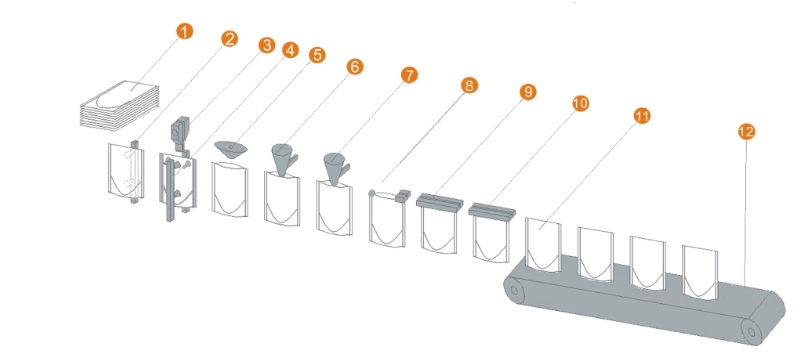

Premade Pouch Fillers:

How They Work: These machines handle pre-manufactured stand-up pouches (often with spouts or zippers already attached). Pouches are automatically fed from a magazine or de-nested from a stack. The machine opens the pouch, fills it with the product, and then seals it (e.g., cap application for spouted pouches, heat sealing the top for zip pouches, or ultrasonic sealing).

Best For: Spouted pouches, zip-lock pouches, complex pouch shapes, high-value products, lower to medium volumes, applications requiring high-quality graphics already printed on the pouch.

Key Components & Features:

Pouch Handling/Forming: Robust systems to reliably feed film (VFFS) or pick and open premade pouches without jamming or damaging the material.

Product Filling System: This is critical for accuracy and depends on the product:

Liquid Fillers: Piston fillers, pump fillers (gear, lobe, peristaltic), gravity fillers, timed-flow fillers. Often include drip prevention nozzles.

Powder/Granule Fillers: Auger fillers (single or multi-head), cup fillers, net weigh fillers, volumetric fillers. Require dust extraction systems.

Solid Fillers: Pick-and-place systems, vibratory feeders, combination weighers.

Sealing System: Creates a hermetic seal to ensure product integrity and prevent leakage/spoilage.

Heat Sealing: Most common, using heated jaws to melt inner laminate layers.

Ultrasonic Sealing: Ideal for certain films, foils, or products sensitive to heat; uses high-frequency vibrations.

Cap Application: For spouted pouches; cappers torque caps securely.

Gas Flushing (Modified Atmosphere Packaging - MAP): Optional but crucial for extending shelf life (especially food). Injects inert gas (like Nitrogen or CO2) into the pouch headspace before sealing, displacing oxygen.

Control System: Modern machines feature sophisticated PLC (Programmable Logic Controller) and HMI (Human-Machine Interface) touchscreens. Allows recipe storage, parameter adjustment (fill weight, seal time/temp, speed), diagnostics, and integration with factory networks (OEE tracking).

Automation & Integration: High-level machines integrate seamlessly with upstream (pouch denesters, labelers) and downstream (checkweighers, metal detectors, X-ray inspectors, case packers) equipment via conveyors and controls.

Changeover Systems: Quick-change tooling and recipe recall minimize downtime when switching pouch sizes or products. Look for servo-driven adjustments.

Hygienic Design: Critical for food, pharma, and cosmetics. Features include stainless steel construction (304 or 316), smooth surfaces, easy access for cleaning (CIP/SIP options), and compliance with FDA, EHEDG, or GMP standards.

Accuracy & Consistency: Precision filling systems combined with checkweigher feedback loops ensure every pouch meets exact weight or volume specifications, minimizing giveaway and ensuring compliance.

Speed (Pouches Per Minute - PPM): Ranges from small semi-automatic machines (< 20 PPM) to fully automated high-speed lines (> 120 PPM). Choose based on required throughput.

Selecting the Right Machine:

Choosing the optimal stand-up pouch filling machine depends on:

Product Characteristics: Liquid, powder, solid, viscosity, particulates, sensitivity (heat, oxygen)?

Pouch Type & Size: Spoutless, spouted, zipper? Dimensions? Film material?

Required Output Speed (PPM): Current and future needs?

Level of Automation: Semi-auto, automatic, fully integrated line?

Budget: Capital expenditure vs. operational savings (labor, waste reduction)?

Hygiene & Regulatory Requirements: Food-grade, pharmaceutical?

Available Floor Space: Machine footprint and line layout?

Conclusion:

Stand-up pouch filling machines are sophisticated pieces of engineering designed to meet the specific demands of modern flexible packaging. Understanding the fundamental types – VFFS for high-volume formed pouches and premade fillers for complex/spouted designs – along with the critical features like precision filling, reliable sealing, gas flushing, automation, and hygienic design, is essential for selecting the right equipment. Investing in the appropriate machine translates directly to increased efficiency, reduced waste, consistent product quality, extended shelf life, and a stronger competitive position in the dynamic market for stand-up pouch packaged goods.