How to Choose the Packaging Machine for Jelly?A Comprehensive Guide

For jelly beverage manufacturers seeking efficient packaging solutions, understanding equipment specifications based on pouch configurations and operational parameters proves crucial. This guide analyzes machinery selection through primary packaging formats and performance considerations.

1. Packaging Format Analysis

Modern jelly packaging predominantly utilizes four structural categories with subtype variations:

1.1 Stand-Up Pouches (Doypack)

Subtypes: Zipper-top, spouted, straw-attached, and custom die-cut designs

Material considerations: Multi-layer laminates for liquid retention

1.2 Flat Sachets

Variations: Three-edge seal, quad-seal, octagonal designs, and dual-compartment formats

Applications: Single-serve portions and promotional packaging

1.3 Stick Packs

Functional designs: Tear-notch configurations and pressure-sensitive burst seams

Production advantage: High-density linear packaging

2. Equipment Specifications by Packaging Type

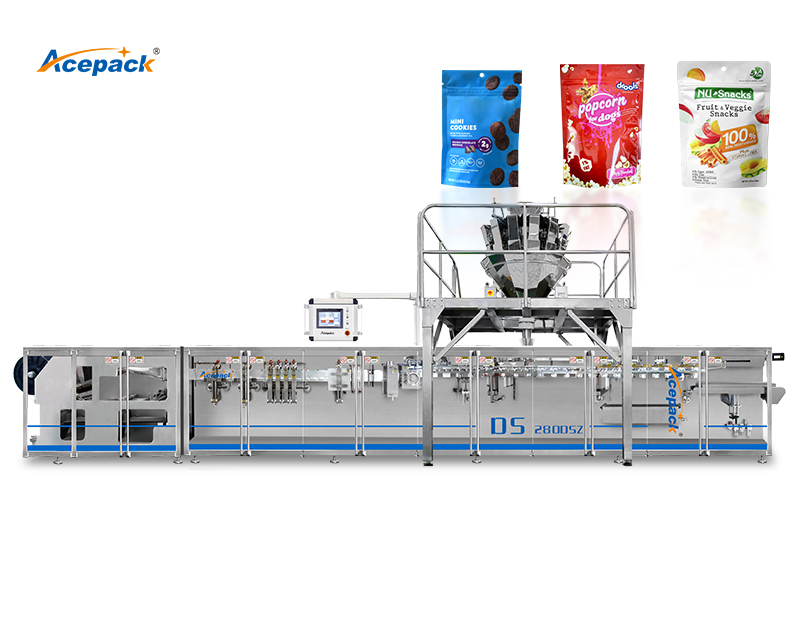

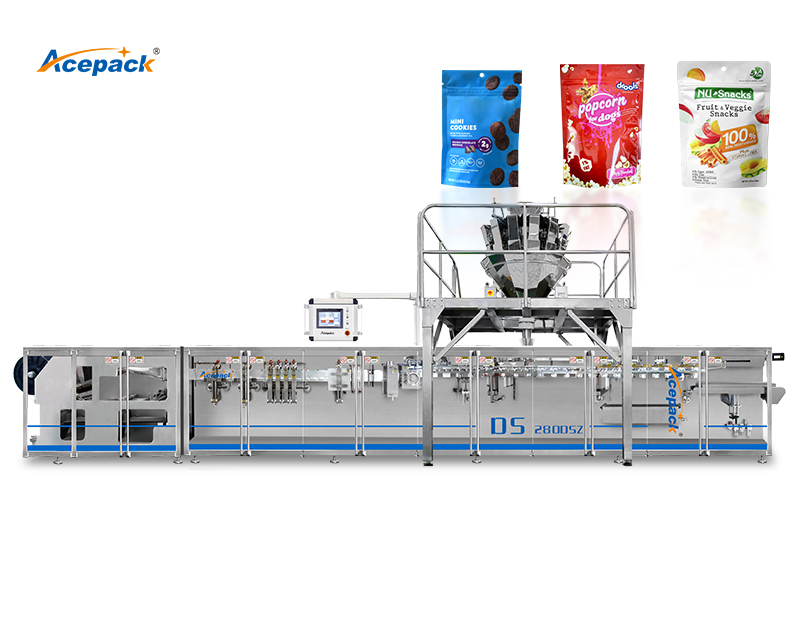

2.1 Horizontal Form-Fill-Seal (HFFS) Systems for Doypacks

Operational capacity: 80-120 pouches/minute (standard configuration)

Automation levels:

Full-automatic HFFS machines with integrated forming collators

Semi-automatic rotary systems using pre-formed pouches

Material handling: Compatible with roll-fed laminates up to 300mm width

2.2 Vertical Form-Fill-Seal (VFFS) Solutions for Flat Sachets

Production output: 40-80 bags/minute (dependent on sealing complexity)

Specialized configurations:

Triple-seam units for premium product presentation

Multi-lane systems achieving 48,000 units/hour throughput

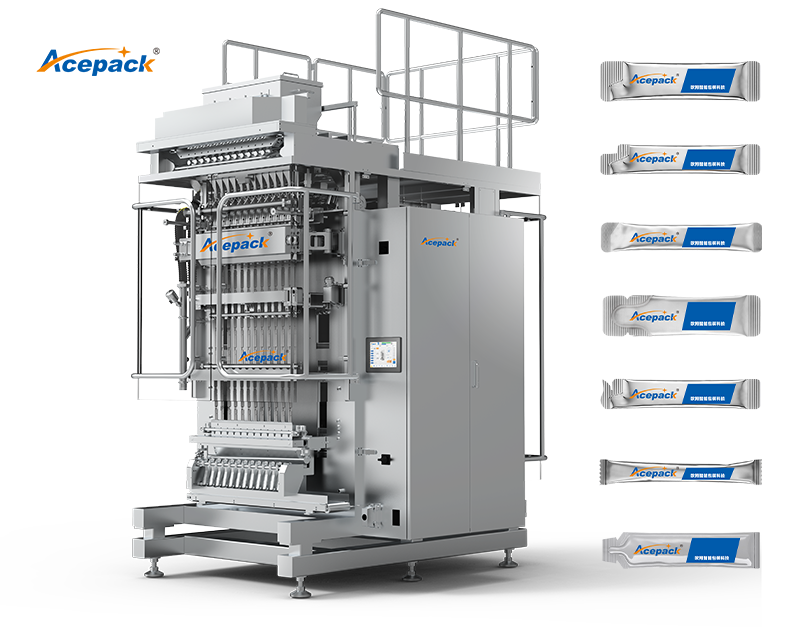

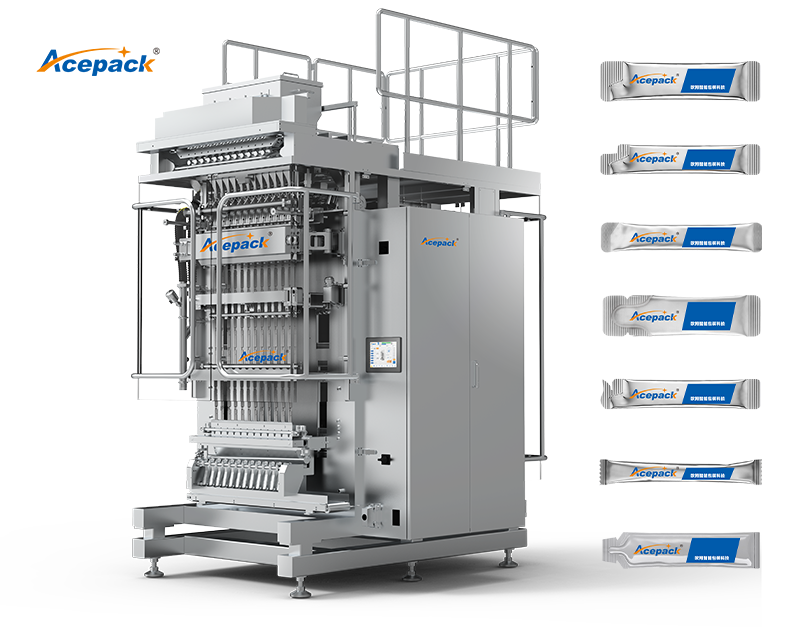

2.3 Stick Pack Vertical Systems

Technical highlights:

Ultrasonic sealing for liquid containment

Multi-head dosing configurations

Operational efficiency: 2,400-4,800 sticks/hour per lane

3. Implementation Considerations

Product viscosity requirements

Retail display specifications

Budgetary parameters (CAPEX vs. OPEX balance)

Facility spatial constraints

Through systematic evaluation of these operational factors and material specifications, manufacturers can identify packaging systems that optimize production efficiency while maintaining jelly product integrity. Acepack's engineering team offers customized consultation services to align machinery capabilities with specific operational requirements, ensuring optimal ROI for jelly packaging investments. Contact our technical specialists for tailored system proposals.