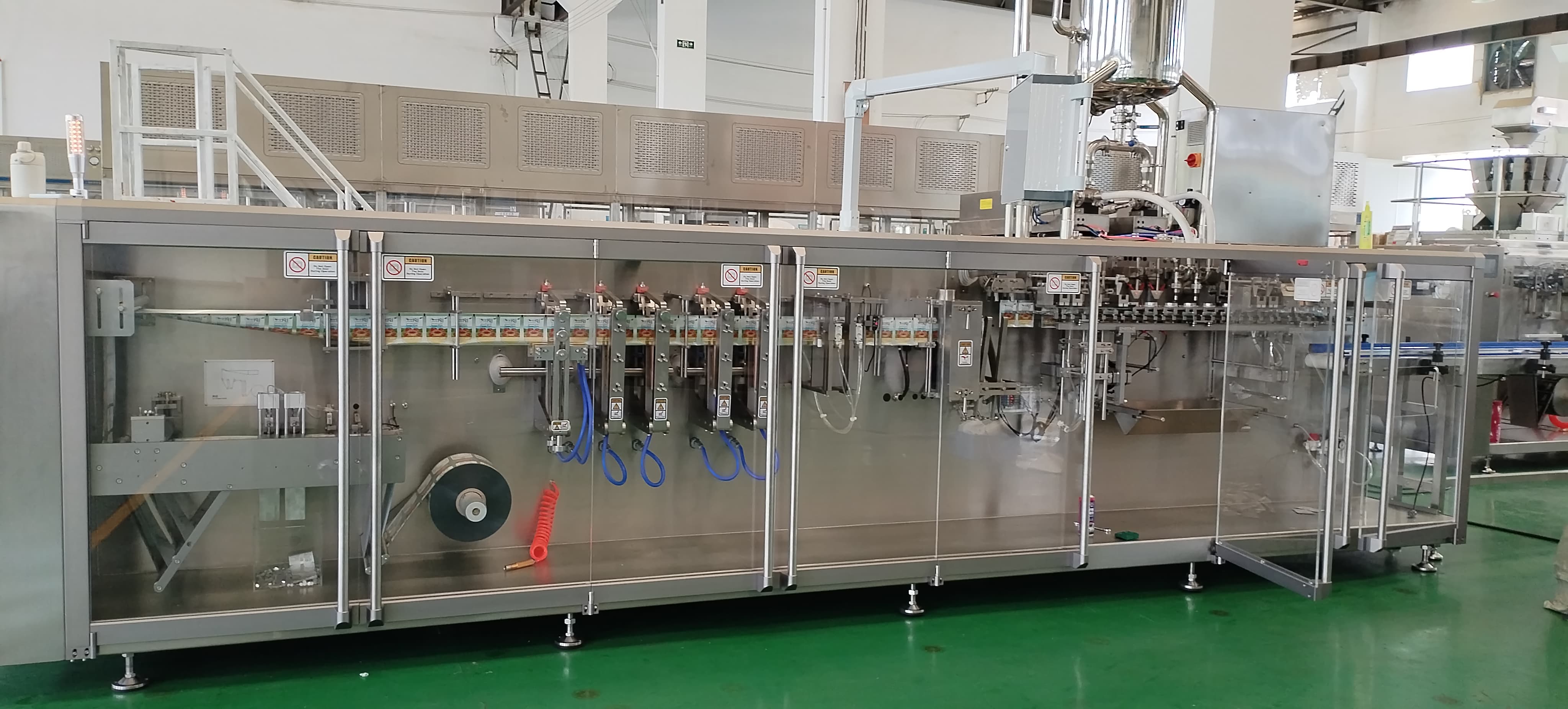

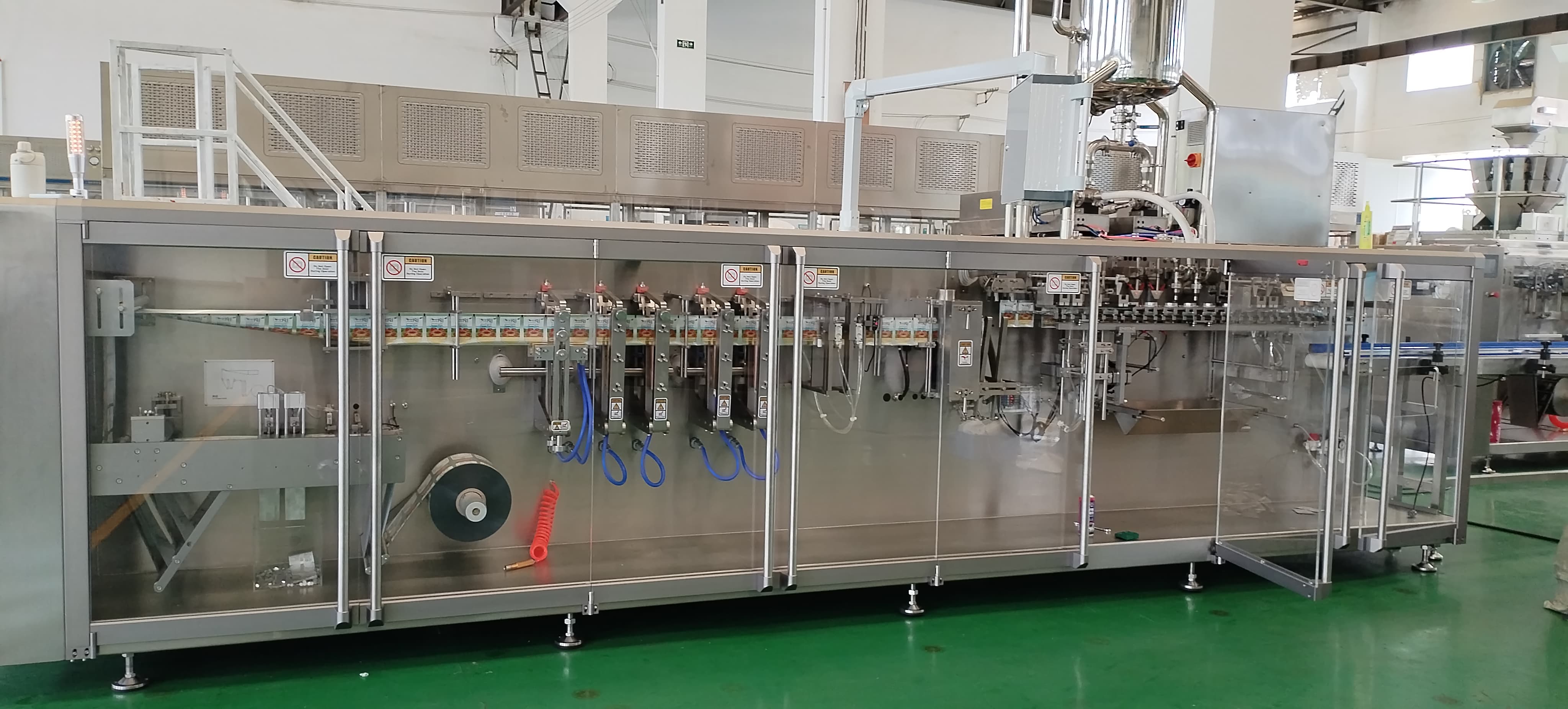

In the fast-paced world of food production, efficiency and quality are paramount. One of the innovations that have gained traction in recent years is the Chill Sauce Sachet 3/4 Side Seal Packaging Machine. In this blog, we will explore the features, benefits, and applications of this machine through a question-and-answer format.

Q1: What is a Chill Sauce Sachet 3/4 Side Seal Packaging Machine?

A1: The Chill Sauce Sachet 3/4 Side Seal Packaging Machine is a specialized piece of equipment designed for packaging liquid sauces, particularly those that require refrigeration. The “3/4 side seal” refers to the method of sealing the sachet on three sides, leaving one side open for filling. This design is particularly effective for maintaining the freshness and quality of sauces, ensuring they remain safe for consumption.

Q2: What types of sauces can be packaged using this machine?

A2: This machine is versatile and can package a variety of sauces, including but not limited to, chili sauce, soy sauce, salad dressings, marinades, and even condiments like ketchup and mustard. The ability to handle different viscosities makes it an ideal choice for manufacturers looking to streamline their packaging processes.

Q3: What are the key features of the Chill Sauce Sachet 3/4 Side Seal Packaging Machine?

A3: Some of the standout features of this packaging machine include:

High-Speed Operation: The machine is designed for high-speed production, allowing manufacturers to package large quantities of sauce in a short amount of time.

Adjustable Filling Volume: It can accommodate various filling volumes, making it suitable for both small and large sachets.

User-Friendly Interface: The machine typically comes with an intuitive control panel, making it easy for operators to adjust settings and monitor the packaging process.

Durable Construction: Built with high-quality materials, the machine is designed to withstand the rigors of a busy production environment.

Hygienic Design: The machine is designed with hygiene in mind, featuring easy-to-clean surfaces and components that minimize contamination risks.

Q4: How does the 3/4 side seal design benefit the packaging process?

A4: The 3/4 side seal design offers several advantages:

Enhanced Seal Integrity: By sealing three sides, the sachet is less likely to leak or burst, which is crucial for liquid products.

Efficient Filling: The open side allows for quick and efficient filling, reducing downtime during the packaging process.

Space-Saving Design: The compact nature of sachets allows for efficient storage and transportation, making it easier for retailers to manage inventory.

Q5: What are the benefits of using the Chill Sauce Sachet 3/4 Side Seal Packaging Machine for manufacturers?

A5: Manufacturers can enjoy numerous benefits by incorporating this machine into their production line:

Increased Productivity: The high-speed operation means that manufacturers can produce more sachets in less time, leading to increased output and profitability.

Cost-Effective: By automating the packaging process, manufacturers can reduce labor costs and minimize the risk of human error.

Improved Product Quality: The machine’s sealing capabilities help maintain the freshness and quality of sauces, which is essential for customer satisfaction.

Flexibility: The ability to package different types of sauces allows manufacturers to diversify their product offerings without investing in multiple machines.

Q6: Are there any specific industries that benefit most from this packaging machine?

A6: Yes, several industries can benefit significantly from the Chill Sauce Sachet 3/4 Side Seal Packaging Machine:

Food and Beverage Industry: This is the primary industry that utilizes this machine, particularly companies that produce sauces, dressings, and condiments.

Catering Services: Catering companies can use sachets for portion control, providing individual servings of sauces for events and gatherings.

Retail: Supermarkets and grocery stores can offer a variety of sauces in convenient sachet forms, appealing to consumers looking for quick and easy meal solutions.

Q7: How does this machine contribute to sustainability in packaging?

A7: The Chill Sauce Sachet 3/4 Side Seal Packaging Machine can contribute to sustainability in several ways:

Reduced Material Waste: The precise filling and sealing process minimizes excess material usage, leading to less waste.

Lightweight Packaging: Sachets are generally lighter than traditional packaging, reducing transportation emissions and costs.

Recyclable Materials: Many manufacturers are now using recyclable materials for sachets, aligning with eco-friendly practices.

Q8: What should manufacturers consider when investing in this packaging machine?

A8: When considering an investment in the Chill Sauce Sachet 3/4 Side Seal Packaging Machine, manufacturers should evaluate:

Production Volume: Assess whether the machine can meet current and future production demands.

Budget: Determine the budget for purchasing and maintaining the machine, including potential savings from increased efficiency.

Space Requirements: Ensure that there is adequate space in the production facility for the machine and its operation.

Supplier Reputation: Research the manufacturer’s reputation and customer service to ensure reliable support and maintenance.

Conclusion

The Chill Sauce Sachet 3/4 Side Seal Packaging Machine represents a significant advancement in food packaging technology. By understanding its features, benefits, and applications, manufacturers can make informed decisions that enhance their production processes and meet consumer demands. As the food industry continues to evolve, investing in efficient and innovative packaging solutions will be crucial for staying competitive.